Exploration of Thread for their Possible use in Fabrication of Low Cost Diagnostic Microfluidic Device

Rakesh B Kabariya1  and Vimal M Ramani2*

and Vimal M Ramani2*

1Senior Research Fellow, College of Dairy Science, Kamdhenu University, Amreli, India 365601,

2Principal and Dean, College of Dairy Science, Kamdhenu University, Amreli, Gujarat, India 365601,

Corresponding author Email: vimalmramani@gmail.com

DOI : http://dx.doi.org/10.13005/msri/150210

Article Publishing History

Article Received on : 20-04-2018

Article Accepted on : 18-05-2018

Article Published : 21 May 2018

Plagiarism Check: Yes

Article Metrics

ABSTRACT:

The emerging concept of thread-based microfluidics has shown great promise for application to inexpensive disease detection and environmental monitoring. This paper describe the properties of thread for the development of thread based low-cost microfluidics device for the diagnostic, food safety and environmental assay. Various properties of thread like capillary flow, wicking capacity and absorption capacity, make them important to fabricate the low-cost microfluidics device. In this paper, three different thread sample viz. cotton yarn, cotton thread and spun thread were taken and different properties like wicking capacity, fluid capillary flow, absorption capacity were measured as well as Scanning Electron Microscopic (SEM) analysis of the same was also carried out to study the morphology and texture of thread fibers. Data obtained from result indicate that the cotton thread having all the ideal characteristic to fabricate the diagnostic device and thus it is suitable for the fabrication of thread based microfluidics device for the diagnostic purpose.

KEYWORDS:

Diagnostic microfluidic device; Fluid capillary; low-cost; Thread properties.

Copy the following to cite this article:

Kabariya R. B, Ramani V. M. Exploration of Thread for their Possible use in Fabrication of Low Cost Diagnostic Microfluidic Device. Mat.Sci.Res.India;15(2)

|

Copy the following to cite this URL:

Kabariya R. B, Ramani V. M. Exploration of Thread for their Possible use in Fabrication of Low Cost Diagnostic Microfluidic Device. Mat.Sci.Res.India;15(2). Available from: http://www.materialsciencejournal.org/?p=7482

|

Introduction

Thread is long element of polyester, polypropylene, cotton and other fiber. Generally thread is made up of thousands of thin elongated fiber tightly bonded with one another to form twisted structure. Thread have been used for the different purpose from the historic time. Thread having various physical property like tenacity, density, abrasion resistance, thermal resistance, flexibility etc. but out of these the important property like wicking capacity, absorption capacity, fluid capillary flow are very much important for the possible use as a microfluidics. If the particular thread having good ideal characteristic than that thread can be used as a microfluidic device for the different purpose like for the bio medical application, fabrication of microfluidics.

As part of a continuous effort to seek new materials for making low-cost diagnostic devices, threads have been investigated as an inexpensive materials for the fabrication of disposable microfluidic devices. Thread normally refers to twisted fibers and can be combined to make a yarn.1 The voids between these fibers form capillary channels and facilitate liquid flow without the requirement of external pumping, make them suitable for fabricating rapid and inexpensive point-of-care (POC) diagnostics. Thread- and fabric-based microfluidic devices require a few microliters of reagents and analyte sample solutions to perform chemical and biochemical analyses.2

If thread have good ideal characteristic like capillary flow, wicking capacity and absorption capacity, than that thread can be used for the different purpose like for the bio medical application, fabrication of microfluidics etc. Thread based microfluidic device should able to give fast and accurate result and comparatively cheap also. So, that it can be more useful in such developing country where diagnostic laboratory are very limited in number and no more transportation facility is available.

Here, in this paper we analyzed the different sample of thread like spun thread, cotton yarn and cotton thread for their wicking capacity measurement, capillary flow measurement, and absorption capacity measurement and scanning electron microscopic (SEM) observation. The major advantage of the using thread is, it is very cheap material compare to any other material. It is durable, available worldwide, very easy to transport, tear resistance, flexible and light in weight.3

Materials and Methods

Collection of thread sample

For the analysis of different parameter, we have collected different type of thread sample like spun thread, cotton yarn and cotton thread. All these thread were purchased from embroidery market, Surat, Gujarat. Primary screening of thread samples were carried out by fluid capillary flow measurement, wicking capacity measurement and absorption capacity measurement.

Fluid capillary flow measurement of thread

For the measurement of fluid capillary flow along with the thread sample, we have used synthetic color dye solution (phenol red and malachite green, s.d fine chem. limited, India). Solution was fill up in glass beaker (reservoir) at such level, where the thread sample can easily touch the surface of the synthetic color dye solution. All the thread sample were hang on the burette stand, lower surface of threads were bind with rubber cork so that thread can easily dipped in dye solution and then thread samples were dipped in synthetic dye solution. All the thread samples were kept constant for 15 min at room temperature. After completion of 15 min, the thread samples were laid down on the longitudinal surface and then the penetration of fluid towards the thread was measure with help of measuring scale.4

Wicking capacity measurement of thread

Wicking property of thread is one of the most important property of thread. In this measurement the liquid is penetrate towards the thread with help of capillary channels by the antigravity force.5 Likewise, the fluid capillary measurement, here also we have used the burette stand. All the thread samples were hang on the burette stand and glass beaker was fill up with distilled water. Lower ends of thread samples were bounded with rubber cork and threads were set on burette stand in such a way that the lower end of thread remained dipped in the water. Followed by its penetration in the thread fiber. All the thread samples were kept in same position for the 15 min of time at the room temperature. After completion of given time duration, the thread was cut at the portion where the end point of water penetration and measured by the measuring scale.6

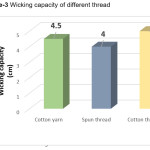

Absorption capacity measurement of thread

Absorption is the ability of thread to retain the water in thread sample. To measure the absorption capacity of thread, thread samples were wetted first and gradually water was transport along with the thread. Absorbance capacity of thread is depend upon the density of fiber.7 All the different thread samples were cut in 30 cm length and then weigh it, it was called as pre-weight of thread sample. Following to the pre-weight, few ml of water in separate petri plate were taken and then all the thread samples were dipped in water for 15 min at room temperature. After completion of time, the thread has been completely sunk in water, than it was taken out from the petri plate and again weighed it, it was called as post-weight. By the difference of pre-weight and post-weight amount of water absorb (regain) by the thread samples was calculated. The liquid absorption capacity of thread was given in percentage.8,9

Scanning electron microscopy (SEM) analysis of thread

Scanning electron microscopic observation was carried out to observe the micro structure and morphology of different thread samples. For the SEM analysis of thread sample, some precaution has been taken for the better analysis, like first sample has been cut in appropriate size to be fit in the specimen chamber, second, thread samples must have electrically conductive surface and electrically grounded to avoid the gathering or accumulation of electrostatic charge on the surface of sample during electron irradiation. In case of the nonconductive specimen or sample like thread, the sample or specimen is going to be charged when it is scanned by the electron beam, especially during the secondary electron imaging mode, this can cause the scanning fault.8,9 So, to avoid this type of problem the sample is generally coated with ultrathin electrically conductive material. After coating the specific sample will use for SEM analysis.

Preparation of thread sample

For this process a small portion (10 mm) of threads were cut and gold coating of several hundred nanometer thickness over the sample using vacuum sputtering machine EMITECH SC 7620 sputter coater at 500 kV for 4 min and pressure current was 10 mA. Thread samples were kept in sample holder (stub) for the SEM analysis.11-13

Analysis of thread sample

Microscopic observation of different thread samples were perform using ZEISS EVO-18 scanning electron microscope having an acceleration voltage of 15 kV. Thread samples were fixed on the aluminum specimen stub with double sticky tap. SEM image data of thread was collected over a selected area of the surface of the sample and a two-dimensional image was visualized that displays properties including micro structure, texture and orientation of thread sample.14

Result and Discussion

Sample of thread include spun thread, cotton yarn and cotton thread were characterized using fluid capillary flow measurement, wicking capacity measurement and scanning electron microscope analysis.

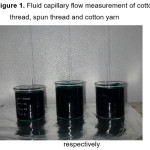

Fluid capillary flow measurement of thread

The fluid penetration distance along threads as a function of time was investigated experimentally by the observation of the capillary rise of the testing fluid against gravity. Table 1 indicate the Penetration of fluid occurred in antigravity direction which was measured using the measuring scale. The recorded result for the fluid capillary flow of different thread samples are as below.

Table 1: Fluid capillary flow measurement

|

Sr. No

|

Name of thread

|

Penetration of fluid along with thread (cm)

|

|

1

|

Cotton thread

|

5.5

|

|

2

|

Spun thread

|

5

|

|

3

|

Cotton yarn

|

4

|

As per Table 1, fluid penetration capacity of fluid was very from thread to thread. Highest fluid penetration capacity of was found in cotton thread-5.5 cm and lowest fluid penetration capacity was found in cotton yarn-4 cm. While in spun thread it was found to be 5cm.

Figure 1: Fluid capillary flow measurement of cotton thread, spun thread and cotton yarn

Figure 2: fluid capillary flow of different thread

From the above result it is said that evaporation is one of the factor that can defeat or decrease the flow of fluid capillary within the fiber during penetration process. This aspect is not consider in above process but may have leading effect on longer time, fluid evaporation can become more and more considerable as the time and fluid on fiber surface can come in contact with open environment. As seen in wicking, here also as the number of twist increase, the flow of fluid capillary will increase. Single twisted thread having low fluid penetration power compare to double twisting, while the triple twisting tread having higher fluid penetration power compare to both single and double twisting.

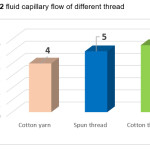

Wicking capacity of measurement thread

Result of wicking capacity of thread is depend upon the viscosity of liquid to be used, temperature, number of fiber present in thread sample etc. Although whatever result was obtain after 15 min time constant which indicate as below. The highest wicking capacity found in cotton thread i.e. 5cm while lowest wicking property was found in spun thread i.e. 4 cm.

Table 2: Wicking capacity measurement of different thread sample

|

Sr. No

|

Types of Thread

|

Wicking of solution (cm)

|

|

1

|

Cotton thread

|

5

|

|

2

|

Cotton yarn

|

4.5

|

|

3

|

Spun thread

|

4

|

Figure 3: Wicking capacity of different thread

In wicking measurement as the number of twist level increase the wicking capacity has increased and it has decreased after it reaching at the maximum value ,the reason behind it has as the twist level increase the size of capillary pore becomes small, so, higher the level of twist, the radius of capillary pore become small. Movement of liquid started to enter in small pores in which wicking action of water was faster because of the higher capillary pressure. Wang et al. (2007) reported that as the number of twist increase in thread, the wicking capacity and capillary flow rate is increasing.

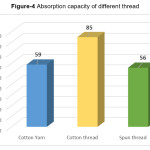

Absorption capacity measurement of thread

We have perform measurement of absorption capacity of different thread samples and we got result of pre-weight and post-weight difference shown in Table 3. The highest absorption capacity of thread was found in cotton thread 85 % and the lowest absorption capacity was found in spun thread 56 % while in case of cotton yarn it was found to be 59%.

Table 3: Measurement of absorption capacity of different thread sample

|

Sr. No.

|

Sample name

|

Length (cm)

|

Pre-weight (gm)

|

Post-weight (gm)

|

Total absorption (%)

|

|

1

|

Cotton thread

|

30

|

0.007

|

0.013

|

85%

|

|

2

|

Cotton yarn

|

30

|

0.095

|

0.187

|

59%

|

|

3

|

Spun thread

|

30

|

0.025

|

0.039

|

56%

|

Figure 4: Absorption capacity of different thread

In absorption measurement, the cotton yarn reached maximum water absorption degree compare to other thread after 15 min of wetting. Higher degree absorption of cotton yarn might be due to the higher amount of cellulose present compare to any other thread sample.

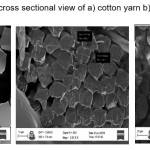

Scanning Electron microscope (SEM) analysis of thread

SEM analysis of all the different thread samples i.e. cotton yarn, spun thread and cotton thread were carried out which is as follow.

Cross section view

Cross section of cotton yarn (Figure 5 (a)) having diameter of 33.49 µm long and 29.84 µm width. Inner surface of fiber was very smooth and flat with almost round in shape. In the cross section, spun thread (Figure 5 (b)) having diameter of 11.17 µm long and 13.28 µm width. Fiber of spun thread was irregular in shape. Starches was clearly seen in cross sectional view. The cross section of cotton thread (Figure 5 (c)) was bean-shaped; however by swelling it was almost round when moisture absorption takes place. Cotton thread having diameter of 17.95 µm in length and 9.1 µm in width. This shape occurs from the inward collapse of the cotton fiber when it dried out.

Figure 5: SEM analysis by cross sectional view of a) cotton yarn b) spun thread c) cotton thread

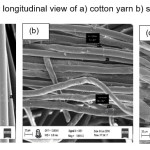

Longitudinal view

The longitudinal view of SEM showed that the cotton yarn (Figure 6 (a)) was flat with a tightly bound in pair and hairless. The absence of folds running the cotton fiber axis was observed. The cotton fiber surface was observed as a smooth fiber surface with no extra stretches. Longitudinal view of Spun thread (Figure 6 (b)) has better aligned fiber with compacted, bundled fiber with minimum protruding fiber. It has rough surface with irregular shape and having diameter of 8.5 mm. Spun thread was gummed by about 300-400 single spun fiber which possess node like structure.

Naturally occurring fold or band was clearly observed with scattering appearance. Under the microscope, the fiber of cotton thread (Figure 6 (c)) was a single elongated cell that is flat twisted and ribbon like structure. These twists are also referred as convolutions. The surface of cotton thread was very rough and stretches was clearly seen on the surface

Figure 6: SEM analysis by longitudinal view of a) cotton yarn b) spun thread c) cotton thread

Conclusion

From the above study it has concluded that the thread having great potential to be studied as a material for microfluidics. This paper describe the use of thread as hydrophilic platform for the fabrication of thread based microfluidic device. Such a device will be inexpensive and suitable for the diagnostic application in developing country. There is an ample opportunities to explore thread as alternative material which have ability to combine with other hydrophilic/hydrophobic material for fabricating diagnostic microfluidics system.

Future Application

The further development of microfluidic technologies for diagnostic applications is expected to flourish and flood our everyday life. Thread based microfluidic device can use for the fast analysis or diagnosis of human disease, environmental monitoring and also for the food safety. Paper based strip device is available for adulteration detection but compare to this, thread based strip will be is more effective and cheap. Development of thread based microfluidic device in food industry can open many new horizons for the instant adulteration detection too.

Acknowledgement and Funding

We would like to appreciate and acknowledge the financial assistance of Department of Biotechnology, Ministry of Science and Technology, New Delhi, Government of India.

Conflict of interest

The author(s) declares that they have no conflict of interest regarding publication of this article.

Reference

- Nie Z., Christian A. N., Gong J., Chen X., Alexander K., Martinez A. W., Max N and Whitesides G. M. Electrochemical sensing in paper-based microfluidic devices. Lab on Chip. 2010;10:477–483.

CrossRef

- Martinez A. W., Phillips S. T., Whitesides G. M. Three-dimensional microfluidic devices fabricated in layered paper and tape. Proc Natl Acad Sci U S A. 2008;105(50):19606-11.

CrossRef

- Martinez A. W., Phillips S. T., Butte M. J and Whitesides G. M. Patterned paper as a platform for inexpensive, low-volume, portable bioassays. Angew. Chem. Int. Ed. Engl. 2007;46(8):1318-1320.

CrossRef

- Ballerini D. R., Li X and Shen W. Flow based control of thread-based micro fluidics devices. Biomicrofluidics. 2011;5:1-13.

CrossRef

- Wang N., Zha A and Wang J. Study on the wicking property of polyester filament. Fibers Polym. 2008;9:1:97-100.

CrossRef

- Ozturk M. K., Nergis B and Candan C. A. A study of wicking properties of cotton-acrylic yarns and knitted fabrics. Text. Res. J. 2010;81:3,324-328.

CrossRef

- Das B., Das A., Kothari V., Fanguiero R and Araujo M. D. Moisture flow through blended fabrics of effect of hydrophilicity. J. Eng. Fiber. Fabr. 2009;4:4:20-28.

CrossRef

- Chatterji P. K and Gupta B. S. Absorbent technol. 2002;416.

- Abramaviciute J., Mukicioniene D and Ciukas R. Static Water absorption of knits from natural and textured yarns. Fibers. Text. East. Eur. 2011;3:86:60-63.

CrossRef

- Dhakal H. N., Zhang Z. Y and Richardson M. O. W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007;67:1674–1683.

CrossRef

- Hossain M. K. Scanning electron microscopy study of fiber reinforced polymeric nano composites. Scan. Electron. Microsc. 2012;731-744.

CrossRef

- Vineis C., Aluigi A and Tonin C. Morphology and thermal behavior of textile fibres from the hair of domestic and wild goat species. UTEX. Res. J. 2008;8(3):68-71.

CrossRef

- Yueping W and Haitao W. G. C. Structures of bamboo fiber for textiles. Text. Res. J. 2010;80:4:334-343.

CrossRef

- Wang G., Han H and Li L. SEM and AFM studies on the surface and cross section morphology of rayon-based activated carbon fibers. Mater. Sci. Forum. 2011;689:413-418.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.

and Vimal M Ramani2*

and Vimal M Ramani2*

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal