UHF and X Band Electro-Magnetic Shielding of Advanced Devices by Some Polymer–Composites

Introduction

In recent years, an explosive growth in use of electrical and electronic devices in industrial, commercial, R & D and home applications has resulted in many-fold increase of generation of electromagnetic waves and, hence, of unwanted electromagnetic interference (EMI) to other devices. Strong EMI certainly has a negative effect, also, on human brain and health.1-5 So, shielding is needed, firstly to prevent unwanted emission of EM waves from some equipment. Secondly, one needs to shield sensitive instruments from EMI so that their performance and life are not compromised. EMI shielding by reflection from metals or materials that possess conducting electrons, is a widely known phenomenon. Metal sheets are the original or 1st generation materials for shielding EMI. But gap-free EMI shielding can be done better and much more readily with a polymer-based flexible EMI shield, the 2nd generation shielding material. Metallic shields are stiffer and heavier than a possible cloth-like shield made from a polymeric composite.6-13 Present trend of replacement of metal cabinets by plastic casings in various instruments is another strong factor in favor of plastic or polymer based EMI shields. EM wave absorption depends on the permittivity ε and/or permeability μ of the shielding materials. Shielding of electromagnetic interference (EMI) by magnetic materials is limited 9 mostly to MHz frequency region, while practical EMI shielding must extend to GHz frequency bands. So, shielding of EMI by magnetic materials will not be considered further in this work.

International Telecommunications Union (ITU) defined ITU Radio Bands like ultra-high frequency (UHF) band covering electromagnetic waves (EM) between 300 MHz and 3 GHz frequency range that corresponds to a wavelength range from 100 mm to 1 meter. UHF waves propagate mainly by line of sight, being blocked by hills and large buildings but penetrating building walls to allow indoor reception. UHF EM waves are used for television broadcasting, cordless phones, walkie-talkies, satellite communication, and many other applications. EM or Radio waves in 3 GHz to 30 GHz frequency range fall into the super-high frequency (SHF) range or microwave frequency range. Waves in SHF range are conveniently referred to by their IEEE radar band designations: S, C, X, Ku, K, or Ka bands, or by similar designations. These are widely used in civil and military radar communications (like weather monitoring, air traffic control, maritime traffic control, defence tracking and speed detection for cars, satellite communications, deep space telecommunications, amateur radio, motion detectors etc). Preset EMI Shielding work is for UHF band and X band EM waves.

Electronic conducting polymers have often been rightly used in polymeric EMI shielding materials. However, these conducting polymers are almost always solids and without any binding capability. Since the other additives that can be used either for enhancing reflection or for inducing absorption, are also solids, one must further add a binder or glue to cast the shielding composite into a sheet. So, it was decided to try composites of a polymeric binder (PB) with either newer absorbing agents (ferroelectric or paraelectric 14, 15 materials) or newer reflecting agents (oxides 16, 17 or metallic systems) or their mixtures. As detailed in next section, Transmittance = T = Pout / Pin = |S12|2 and Reflectance = R = Prefl / Pin = |S11|2 for electromagnetic waves have been measured by a vector network analyzer (VNA) as a function of EM wave frequency in UHF and X band for the above-mentioned polymer composites, developed for this work.

Materials and Methods

Materials Selection

Following solids have been selected to form polymer-solid composites for shielding:

Absorbing Agents

(a) BaTiO3 powder (a ferroelectric material with ε = 2500 to 3000 & dielectric loss, tanδ, ≤ 0.015 18 and exhibiting Tc (Curie Temperature) ~ 132 ºC with good piezoelectric properties e.g. piezoelectric constant, d33= 788 pC/N 19, 20), and (b) orthorhombic PbNb2O6 (the ferroelectric phase, with ε = 115 to 150 and tanδ = 0.00845 to 0.1127 and exhibiting Tc > 570 ºC piezoelectric properties 15, 21).

Reflecting Agents

(a) fine brass and copper turnings (fibers), found as waste in machining workshops, and (b) CdO_800 and CdO_270, cadmium oxide turned fairly conducting by innovative firing 16, 17 at 800ºC and 270ºC, as well as CdO_RT (dried cadmium oxide without any high temperature firing) as reference.

Mixed Materials

Kaynak et al. 22 achieved maximum shielding efficiency of 40 dB at 1 GHz using composites of polypyrrole, a conducting polymer. It appears that EMI shielding has not been studied earlier with our composites. Our choice of barium titanate and or lead metaniobate as the shielding partner in the present work is based on the expectation that inorganic materials like these dielectric and piezoelectric substances can absorb incident EM waves efficiently to cut down transmission. Our observation of low electrical resistance in 800ºC fired 16, 17 cadmium oxide, making it conducting, has inspired its use as the shielding partner, hoping large reflection of incident EM wave. Instead of well-known metal or alloy powder as the shielding partner of the polymeric composite, fine copper and brass turnings (fibers), found as waste in machining workshop, have been processed and used to lower product cost. These metallic (Brass and Copper) turning composites show negligibly low transmission: 10 log (Pout / Pin) = -17.22 to -31.66 dB for a Brass-composite, and -16.42 to -32.87 dB for a Cu-composite, in 08 to 12 GHz range.

Material Preparations and Characterization

BaTiO3

Single phase barium titanate, BaTiO3 (to be abbreviated as BT) samples have been prepared from BaCO3 and TiO2 powders using solid state reaction, by few firings at ~ 1300º C for a total time of 12 hours. It has been characterized by X-ray diffraction (XRD) as a tetragonal phase with structural parameters, a = 3.9943 Å, b = 3.9943 Å, c = 4.0307 Å, α = β = γ = 90º. Transmission electron microscope (TEM), measured d = 3.9947 Å for (100) plane (in Figure 1a and 1b), matching d = 3.9949 Å, calculated by Rietveld XRD analysis (Figure 1d). Differential Scanning Calorimetry (DSC), gave ferroelectric to paraelectric phase transition temperature (Tc) at 124.3 ºC, agreeing with 120 ºC< Tc23. All the results have been shown in Figure 1, our positron lifetime spectroscopy being recorded in.14

PbNb2O6

Lead Metaniobate, PbNb2O6, samples have been prepared from PbO and Nb2O5 powders using solid state reaction, by firing at three stages: 1050°C for 3.5 hours, 1290°C for 1 hour and 1270°C for 5 hours in a box furnace with PID (Proportional-Integral-Derivative) temperature controller. After the last firing, the sample has been quenched from 1270°C to room temperature within a few minutes to get the orthorhombic lead metaniobate (to be abbreviated as PN). The structure has been orthorhombic with structural parameters a = 17.6705 Å, b = 17.9841 Å, c = 3.8764 Å, α = β = γ = 90º, identified using XRD (in Figure 2e). TEM techniques, measured d = 5.637 Å for (130) planes (Figure 2b and 2c), matching d = 5.663 Å, calculated by Rietveld analysis (Figure 2e and 2f) of our XRD data. Figure 2 shows ferroelectric properties as found by DSC 15, 24-25, giving ferroelectric to paraelectric phase transition temperature at 569 ºC for powder sample (indicated by black color in Figure 2a) and 570.4 ºC for bulk sample (indicated by red color in Figure 2a). This result supported by Impedance Spectroscopy.15, 21

Figure 1: DSC signal of BaTiO3 sample shows ferroelectric to para-electric transition at 124.3ºC. Insets (a) and (b) are HRTEM view of its microstructure, while (c) is the electron diffraction pattern for (100) planes, shown in (b). XRD for this BaTiO3 sample is shown in (d). XRD value of d = 3.9949 Å for the (100) planes, giving peak at 22.048º) in Figure 1(d), matches well with d = 3.9947Å from TEM diffraction pattern.

Fired CdO

As-supplied cadmium oxide (E Merch, India) has been heat treated in air in a Carbolite furnace for 36 hours at 270º C followed by cooling set at 800 ºC/h rate, resulting in, CdO_270. CdO_800 samples have been similarly prepared by 800ºC firing. The as-supplied sample, to be called CdO_RT, has been dried at ~ 75ºC and used. 4-probe electrical measurement shows (Figure 3) large improvement of electrical conductivity on firing as-supplied cadmium oxide at high temperatures presumably due to oxygen loss.17.

Figure 2: DSC signal of PN35Q sample, in Figure 2(a), shows ferroelectric to ferroelectric transition at 569 ºC (for the powdered sample, indicated by continuous black line) and at 570.4 ºC (for the bulk sample, indicated by continuous red line). Insets (b), (c) and (d) are HRTEM results for one of the observed sets of planes – (130) planes to be specific. XRD pattern is shown insets (e) and (f). Here, d = 5.663 Å, measured from XRD for the (130) planes that gave the x-ray peak at 15.636º and d = 5.637 Å, measured from TEM diffraction pattern, match fairly well.

Figure 3: Variation of room temperature electrical resistivity of heat treated cadmium oxide with firing temperature. Low resistivity of 800°C fired “CdO” may be noted.

Brass and Copper turnings composites:

The fine brass and copper turnings were cleaned and sieved, in order to select only those which pass through 1mm x 1mm area. The polymeric binder for the composites is a sealant, commercially available as a thick liquid inside its tube. Overnight curing in air of the binder or the binder-powder composite resulted in rubber-like sheets of controllable thicknesses and sizes. In this way, composites were prepared from the above ingredients mixed in various proportions. Each composition was mixed homogeneously and allowed to cure overnight into flexible sheets. Each sheet was cut into a rectangular shape or into an annular ring of such sizes as to meet the rectangular wave guide (for X-band) or coaxial holder (for UHF-band) requirements of the vector network analyzer. Coaxial holder samples have been photographed and shown in Figure 4(i) before presenting the results in Figure 4(ii).

Figure 4: Figure 4(i) shows our Annular Samples for 700MHz to 3GHz EMI shielding measurements with the Vector Analyzer. Figure 4(ii) shows variation of shielding effectiveness of the pure polymeric binder (a), and of polymeric composites: (b) with 800°C fired CdO, one layer (CdO_800 33I sample), (c) with BaTiO3 (BT31 sample), (d) with CdO & BaTiO3 (CdO_800 BT 34 sample), (e) with CdO_800, 2 layers (CdO_800 33II sample), (f) with CdO_800, 3 layers (CdO_800 33III sample), in the frequency range 700MHz to 3GHz. More detailed sample description has been given in the text and Table 1.

Electromagnetic Shielding Measurement

Input power (Pin) for an EMI shield (the test material), the reflected power (Prefl) and the transmitted power (Pout) can be measured by a vector network analyzer (VNA) as a function of EM wave frequency. The 2-port network parameters S12 = S21 (for transmission) and S11 (for reflection) are related to transmittance and reflectance:

T = Transmittance = Pout / Pin = |S12|2 and R = Reflectance = Prefl / Pin = |S11|2.

If R = reflected fraction of EM wave intensity, A = absorbed fraction and T = transmitted fraction, R+A+T = 1.

For quantitative estimate of total shielding one defines:

SE = Shielding Effectiveness in dB unit = 10 log (Pout / Pin).

Since Pout < Pin, SE will be a negative quantity. A large negative value will, therefore, indicate high shielding.

Since Shielding Effectiveness, as defined above, is a negative quantity, many authors 18, 26-27 define:

Shielding Efficiency = – 10 log (Pout / Pin) in dB = 10 log (Pin/Pout) in dB,

which has higher positive value (larger Pin/Pout) for materials that shield more.

Similarly, 10 log (Prefl / Pin) in dB = Reflection Effectiveness = RE,

is a negative quantity, with – 10 log (Prefl / Pin) in dB = Shielding Efficiency arising from reflection only. However, the terminology in certain treatise is often different from what we present here. One must take note of such differences to avoid confusion. Absorbed power = Pin – Pout – Prefl can be estimated easily. A coat of a Radar absorbing Material or RAM on a military aircraft must absorb most or almost all of any searching radar beam incident on an aircraft, if the aircraft wants to evade radar detection.

As already indicated, EMI shielding can be due to either reflection of EM waves or absorption or both, ignoring the minor effect of internal reflections. Total SE or Shielding Effectiveness can be expressed as a sum:

SE = SEtotal = SEreflection + SEabsorption

All shielding measurements were done using a Vector Network Analyser E8364B supplied by Agilent Technologies mainly over 8 to 12 GHz (X-band) and also at a lower frequency range of 700 MHz to 3 GHz (part of ultra high frequency (UHF) band). Rectangular wave guide system is used in the 8 to 12 GHz (X-band) run, while the 700 MHz to 3 GHz measurement is based on coaxial holder. Presently used VNA gives the variations of 10 log (Pout / Pin), related to S12, and 10 log (Prefl / Pin), related to S11, with frequency graphically, with digital data for selected representative points only. So, polynomial fit to these data points and additional points read from the graph has been done to get a digital representation of the machine output over the full range of frequency. In later figures showing shielding and reflection results, solid line graphs of the fitted polynomials together with machine supplied plus read data points have been presented. A straight line approximation of the polynomial fit is presented in some cases.

Results and Discussion

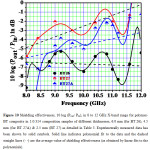

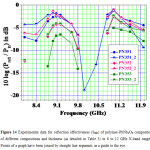

Six representative graphical result sheets of the Vector Network Analyser have been presented in Figure 4, Figure 4(ii) to be precise. Each sheet shows, in different colors, 10 log (Pout / Pin) in dB = Shielding Effectiveness arising from transmission and depending upon reflection and absorption, and 10 log (Prefl / Pin) in dB = Reflection Effectiveness. Figure 5 (adapted from 27) shows Shielding Effectiveness, 10 log (Pout / Pin), against frequency in the range 700 MHz to 3 GHz for composite samples of PB + CdO_800 (1:0.19 by wt.), PB + BT (1:0.434 by wt.), PB + BT + CdO_800 (1:0.207:0.205 by wt.). EM wave absorption is clearly much less in this range (< 3 GHz) than that in higher frequency (> 3 GHz) ranges. Moreover, we find almost no variation of shielding (for different compositions) below 2 GHz, and little variation between 2 and 3 GHz. Still, there are some interesting features for the reflective Shielding Effectiveness, as discussed below.

Figure 5: Variation, in the range 0.7 to 3GHz, of EMI shielding effectiveness in transmittance mode of polymeric composite with BaTiO3 (BT 31 sample), with 800°C fired CdO (CdO_800 33 sample) and with a mixture of the two (CdO_800 BT 34 sample), adapted from [22].

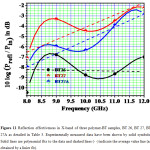

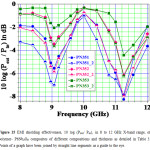

Figure 6: Variation with frequency, over the range 0.7 to 3GHz, of shielding effectiveness (linked to S12 and shown by broken line joining half-filled symbols) and reflection effectiveness (linked to S11 and shown by continuous line joining fully-filled symbols) of different polymer-PN samples. Compositions (PB:PN) of differently named polymer-PN samples are indicated in Table 1.

Shielding Effectiveness, 10 log (Pout / Pin), arising from reflection and absorption, and Reflection Effectiveness, 10 log (Prefl / Pin), have been shown in Figure 6, as a function of frequency in the range 700 MHz to 3 GHz for composite samples of PB and PN with different wt. ratio and different thickness (Table 1). Transmission and reflection part are very low and almost constant up to 1.36 GHz, then increases up to 3 GHz decreased the shielding efficiency up to 3 GHz for all measured PN polymer composites. Figure 6 shows that the values of shielding effectiveness and shielding efficiency remain unchanged in spite of the composite weight fraction variations (95.2%, 55.2% and 13.4% with PB in wt. ratio for PN351, PN352 and PN353 sample respectively). Pure PB, sample (a) in Figure 4, has very low reflection (reflective shielding effectiveness better than -30 dB) over 800 MHz to 1.62 GHz range with a deep minimum at 1.33 GHz. This minimum shifts in location (frequency) and magnitude in different composites of the PB. However, in all cases, samples (a) to (f), transmission remains high as the 10 log (Pout / Pin) graph is always just below its zero value. It is a case of low reflection with low absorption and high transmission as depicted in Figure 4 and discussed in next paragraph. So, these are not good as radar absorbing material, in spite of low reflection. Our effort to develop radar absorbing material will continue.

Adding 19 wt.% of CdO_800 to the polymeric binder, shifts the reflection minimum to a lower frequency of 1.28 GHz and creates a second reflection minimum at 2.20 GHz. In PB-BT composite with 43.4 wt.% BT (say BT 31 sample), however, the reflection minimum shifts to a lower frequency of 1.16 GHz. So, the two additives, CdO_800 and BT, affect EMI shielding oppositely. Result for the composite PB +CdO_800+BT (1:0.37:0.185 by wt., say CdO_800 BT 34 sample), sample (d), is shown in Figure 4, while in PB+BT+CdO_800 (1:0.207:0.205 by wt., called CdO_800 BT 32 sample), not shown in the figure, the reflection minimum is at ~1.40 GHz. Thickness dependence of EM reflection has been studied here by EMI shielding measurement on stacks of 2 and 3 layers of the sample pieces (each with ~ 2.5 mm thickness), and the dependence is similar in all samples. It is shown in Figure 4 for PB+19.4 wt.% of CdO_800 material (CdO_800 33 II sample, for example) for 2-layered sample (e) and 3-layered sample (f). There is more reflection in samples (e) and (f) than in the single-layered sample (b).

Measurement of EMI shielding over 8 to 12 GHz range for the metallic composite, PB:metal (brass) = 1:0.4854 (say Brass 41 sample), shows very low transmission (Figure 7) i.e. high EMI shielding, and rather large reflection (Figure 8). Shielding effectiveness values can be seen from the figures. So, this polymeric composite of fine brass turnings imitate the efficient shielding property of metal (brass) sheet quite well. However, the cadmium oxide composite PB:CdO_800 = 1:1.447 (say CdO_800 42) does not reflect (Tables 2-4) the EM waves significantly (Figure 8) in spite of the high electrical conductivity (Figure 3) of CdO_800. Figure 7 shows the variation of Shielding Effectiveness for different composites samples (Brass 41, CdO_800 42, Brass CdO_800 43 and PB22). Pure brass composite sample offers better EMI shielding in X band than other samples like pure CdO_800 composite or brass with CdO_800 composites. Brass 41 samples let only 1.78 to 0.056% EM wave transmissions where as Brass CdO_800 43 sample gives 1.0 to 31.6% and CdO_800 42 sample 56.2% EM wave have been transmitted of the incident EM waves in X-band regions.

Figure 7: (a) Shielding effectiveness in 8 to 12 GHz range for pure Polymeric Binder (square symbol & graph), its composite with brass (down triangle & graph), its composite with CdO_800 (circle symbol & graph) and its composite with brass & CdO_800 (up triangle symbol & graph). The data points (different symbols) indicate values directly printed by the Vector Network Analyser. VNA machine gives results also as graphs, (b) and (c). Our continuous graphs are from polynomial fits to representative points read from the graphs (b) and (c).

Figure 8: Reflection effectiveness, 10 log (Prefl / Pin), in 8 to 12 GHz frequency range, of polymer composites with brass turnings (Brass 41), with brass turnings & CdO_800 (Brass CdO_800 43), and with CdO_800 only (CdO_800 42). All solid symbols are machine data collected from VNA instrument and the matching solid lines indicate the polynomial fits to the data sets. Moreover, linear fits to these polynomials are given by corresponding open symbols.

The Reflection Effectiveness (RE) of three composite polymer sheets, Brass 41, Brass CdO_800 43, CdO_800 42 in X band range, have been shown in Figure 8. Pure brass composite polymer sample, Brass 41, reflected the EM wave energy better, ~ 34% on average (~ 55% at 8 GHz to ~ 20% at 12 GHz) in X-band. When we added conducting powder (CdO_800 (44% wt. ratio) for example), to the brass (22%) composite sample, it reflected ~ 34% of EM wave energy on average (~ 54% at 8 GHz to ~ 23.9% at 12 GHz). But pure CdO_800 (44.7%) composite reflected only ~ 12.8% of the EM wave energy on average (~ 5.5% at 8 GHz to ~ 33% at 12 GHz). Addition of CdO_800 powder with brass composite polymer, Brass CdO_800 43 sample, gives deep reflection peak, less wide than Brass 41 sample and shifting the position towards lower frequency (~ 10.5737GHz (~ 20.4%) to ~ 9.600 GHz (~ 9.9%)). For pure CdO_800 polymer composite this peak shows more width than Brass CdO_800 43 sample and shifted towards lower frequency at ~ 9.2984 GHz (~ 3.2%). The shielding effectiveness (SE) of two types of polymeric composites, one set with brass and another set with copper (Cu) will now be presented for different composition ratios (by wt.) and for different thicknesses. For example, we have Brass 41 (~ 48.5% brass with thickness = ~ 3.58 mm), Brass 23 (~ 59.6% brass with thickness = ~ 3.00 mm), Brass 24 (~ 59.6% brass with thickness = ~ 4.75 mm). The Cu-polymer composite Cu 51 has ~ 49.7% Cu with thickness = ~ 2.19 mm, studied in X band range in Figure 9. Brass 23, Brass 24 and Brass 41 samples are formed by same composite materials but with different composition ratio. Brass 41 sample transmitted only ~ 0.19% of EM wave energy at the minimum, found at ~ 11.599 GHz. Brass 23 and Brass 24 samples transmitted ~ 38.3% EM wave energy at the minimum at ~ 11.1979 GHz and ~ 43.1% at the minimum at ~ 9.9946 GHz, respectively. Cu 51 sample shielded the EM waves to ~ 10.75 GHz better transmitting only ~ 0.05% (at the 1st min. at ~ 10.385 GHz) and ~ 2.3% (at the 2nd min. at ~ 9.580 GHz). From Figure 9, we observe that SE is thickness independent in the range of study and it depends on the composition ratio of the sample. In a particular composite ratio (48.5% of brass, in Brass 41 sample) sample gives better shielding performance. The shielding effectiveness (SE) of BaTiO3 composite polymers with different thickness, formed three sheets for examples BT 26 (~ 31.4% BaTiO3 with thickness = ~ 6.0 mm, giving average transmission of ~ 21.6%), BT 27 (~ 31.4% BaTiO3 with thickness = ~ 2.5 mm and an average ~ 55.9% EM wave energy transmitted), BT 27A (~ 31.4% BaTiO3 with thickness = ~ 4.5 mm, giving average transmission of ~ 34.5%), as shown in Figure 10. Here, we observe that the shielding performance increased with increasing the thickness of samples. The RE of BaTiO3 composite polymers with different thicknesses, formed three sheets: for examples, BT 26 (~ 31.4% BaTiO3 with thickness = ~ 6.0 mm, giving average reflection of ~ 14.8%, BT 27 (~ 31.4% BaTiO3 with thickness = ~ 2.5 mm, giving average reflection of ~ 38.7%, BT 27A (~ 31.4% BaTiO3 with thickness = ~ 4.5 mm, giving average reflection of ~ 29%, in X band range, as shown in Figure 11. Here, we observe that the reflected energy decreased with increasing the thickness of samples. i.e., absorption power increased with increasing the thickness of samples.

Figure 9: Shielding effectiveness in 8 to 12 GHz range of X-band for three polymer-brass composites and one copper composite, with Table 2 giving composition and thickness against sample name. Experimentally measured data points have been shown by solid symbols and the polynomials fits by continuous lines of same colors. Moreover, average value of shielding effectiveness is found for Brass 41 and Cu 51 samples by the straight line fits to the corresponding polynomials and indicated in the figure by hollow triangles (in olive color) and hollow circles (in blue color).

Figure 10: Shielding effectiveness, 10 log (Pout/ Pin), in 8 to 12 GHz X-band range for polymer-BT composite in 1:0.314 composition samples of different thicknesses, 6.0 mm (for BT 26), 4.5 mm (for BT 27A) & 2.5 mm (BT 27) as detailed in Table 3. Experimentally measured data has been shown by solid symbols. Solid line indicates polynomial fit to the data and the dashed straight lines (- -) are the average value of shielding effectiveness (as obtained by linear fits to the polynomials).

Figure 11: Reflection effectiveness in X-band of three polymer-BT samples, BT 26, BT 27, BT 27A as detailed in Table 3. Experimentally measured data have been shown by solid symbols. Solid lines are polynomial fits to the data and dashed lines (- -) indicate the average value line (as obtained by a linier fit).

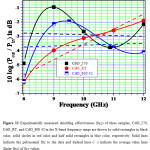

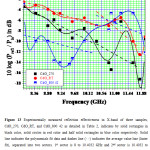

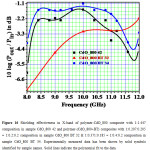

The Reflection Effectiveness (RE) of CdO composite polymers with different thickness, different composition ratio, and different firing temperature, are presented in three sheets: for example, CdO_800 42 (~ 144.7% CdO_800 with thickness = ~ 2.05 mm), CdO_270 (~ 8.5% CdO_270 with thickness = ~ 2.23 mm), CdO_RT (~ 11.1% CdO_RT with thickness = ~ 2.88 mm), as shown in Figure 12. Here we observe that CdO_RT sample shields the incident wave better than other two samples (CdO_800 42, CdO_270) only in the frequency ranges “8 to ~ 9.76 GHz”, and in “~11 to 12 GHz” range CdO_800 42 sample prevents better transmission through the sample of the incident EM waves, due to its high conductivity. The RE of three CdO composite polymers, CdO_800 42, CdO_270, and CdO_RT in the X band range, has been shown in Figure 13. The frequency range has been change into two sectors on the basis of RE property of the measured samples. We observe that in the lower frequency sector (8 to ~10.4 GHz) CdO_RT sample reflected better (on average ~ 33.6%) the incident EM waves than other two samples (CdO_270 with average RE = 19.8% and CdO_800 42 with average RE = 8.7%). But in the 2nd sector (~10.4 to 11.8 GHz) CdO_800 42 sample reflected better (on average ~ 21% ) the incident EM waves than other two samples (CdO_RT with average RE = 16.6% and CdO_270 with average RE = 5.2%).

Figure 12: Experimentally measured shielding effectiveness (SET) of three samples, CdO_270, CdO_RT, and CdO_800 42 in the X-band frequency range are shown by solid rectangles in black color, solid circles in red color and half solid rectangles in blue color, respectively. Solid lines indicate the polynomial fits to the data and dashed lines (- -) indicate the average value lines (linier fits) of SET values.

Figure 13: Experimentally measured reflection effectiveness in X-band of three samples, CdO_270, CdO_RT, and CdO_800 42 as detailed in Table 2, indicates by solid rectangles in black color, solid circles in red color and half solid rectangles in blue color respectively. Solid line indicates the polynomials fit data and dashes line (- -) indicates the average value line (linier fit), separated into two sectors. 1st sector is 8 to 10.4032 GHz and 2nd sector is 10.4032 to 11.818956 GHz.

Figure 14: Experimental data for reflection effectiveness (SER) of polymer-PbNb2O6 composites of different compositions and thickness (as detailed in Table 3) in 8 to 12 GHz X-band range. Points of a graph have been joined by straight line segments as a guide to the eye.

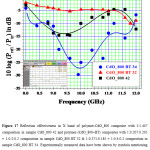

The RE (in X band range) of six PN composite samples, PN351 (~ 95.2% PN and single layer), PN351_2 (double layers of PN351 sample), PN352 (~ 55.1% PN and single layer), PN352_2 (double layers of PN352 sample), PN353 (~ 13.4% PN and single layer) and PN353_2 (double layers of PN353 sample) has been shown in Figure 14. Here, we observe that the reflected fraction of EM wave energy increases with the increase of the thickness of the sample. For examples, PN351 sample reflects ~ 44.5% of the incident EM waves, whereas PN351_2 sample reflects ~59.6%. Similarly, PN352 sample reflects ~ 20.2% of the incident EM waves, whereas PN351_2 sample reflects ~ 49.1%. Also, PN353 sample reflects ~ 4.5% of the incident EM waves, whereas PN353_2 sample reflects ~ 21.9% at ~ 8.8 GHz. It is also observed that the reflection increases as the fraction of the active component is increased. SE in X band range of the six PN composite samples, PN351, PN351_2, PN352, PN352_2, PN353 and PN353_2 has been shown in Figure 15. We observe that the transmitted fraction decreases with increase of the fraction of active component and the thickness of the sample. For examples, PN351 sample transmits ~ 15% of the incident EM waves, whereas PN351_2 sample transmits ~16.4%. Also PN352 sample transmits ~ 24.3% of the incident EM waves, whereas PN352_2 sample transmits ~15.9%. Similarly, PN353 sample transmits ~ 36.4%, whereas PN353_2 sample transmits ~23.7%, at ~ 11.2629 GHz. In lower frequency range (at ~ 9.07 GHz, PN351 sample transmits~ 27.9% of the incident EM waves, whereas PN351_2 sample transmits ~19.8%. PN352 sample transmits ~ 45.3% of the incident EM waves, whereas PN352_2 sample transmits ~25.7%. Finally, we note that PN353 sample transmits ~ 62.3% of the incident EM waves, whereas PN353_2 sample transmits ~ 42.9%.

Figure 15: EMI shielding effectiveness, 10 log (Pout/ Pin), in 8 to 12 GHz X-band range, of polymer- PbNb2O6 composites of different compositions and thickness as detailed in Table 3. Points of a graph have been joined by straight line segments as a guide to the eye.

Figure 16: Shielding effectiveness in X-band of polymer-CdO_800 composite with 1:1.447 composition in sample CdO_800 42 and polymer-(CdO_800+BT) composites with 1:0.207:0.205 = 1:0.2:0.2 composition in sample CdO_800 BT 32 & 1:0.371:0.185 = 1:0.4:0.2 composition in sample CdO_800 BT 34. Experimentally measured data has been shown by solid symbols identified by sample names. Solid lines indicate the polynomial fit to the data.

SE in X band range of three samples, one with only CdO_800 (CdO_800 42 sample with 144.7% CdO_800) and another two mixed composites (conducting powder, CdO_800, and dielectric powder, BaTiO3 (BT), mixed with polymeric binder in different ratios) – CdO_800 BT 32 (20.7% CdO_800 and 20.5% BT), and CdO_800 BT 34 (37.1%, CdO_800 and 18.5%, BT) – has been shown in Figure 16. It shows that the CdO_800 BT 32 sample shields the EM waves better than other two samples in the range 8 to 11GHz. But 11 to 12 GHz range finds CdO_800 42 sample shielding the EM waves better than other two samples (CdO_800 BT 34 and CdO_800 BT 32). The RE in X the band range of three samples, one with only CdO_800, and two mixed composite samples – CdO_800 BT 32 and CdO_800 BT 34 – has been shown in Figure 17.

Figure 17: Reflection effectiveness in X band of polymer-CdO_800 composite with 1:1.447 composition in sample CdO_800 42 and polymer-(CdO_800+BT) composites with 1:0.207:0.205 = 1:0.2:0.2 composition in sample CdO_800 BT 32 & 1:0.371:0.185 = 1:0.4:0.2 composition in sample CdO_800 BT 34. Experimentally measured data have been shown by symbols mentioning sample names. Solid lines are polynomial fits to the data.

From Figure 17, we observe the CdO_800 BT 32 sample to reflect better the EM waves than other two samples in the range 8 to ~11GHz. But 11 to 12 GHz range finds CdO_800 42 sample reflecting the EM waves better than other two samples. At 9.9046 GHz frequency CdO_800 34 sample reflects only 0.11% of the incident wave energy and transmitted ~ 74.4% (from Figure 16). Same figure shows that CdO_800 42 sample and CdO_800 32 sample reflect ~ 5.7% (transmitted ~71%, Figure 16) and ~ 32.5% (transmitting ~ 48.5%, Figure 16), respectively. CdO_800 34 sample (absorbing 25.5%) has better absorption power than CdO_800 42 (23.3% absorbed) and CdO_800 32 (19.1% absorbed).

Even without optimization, some metal turnings composites show negligibly low transmission (~ -16 to ~ -34dB in 08 to 12 GHz range) 7. A polymeric composite of a conducting oxide shows a deep reflection minimum of about -30 dB (at 9.71 GHz) 7, important for Radar Absorption Materials or RAM. The width of this minimum (9 to 10.5 GHz) could be increased by adding a third component.

Table 1: SE = Shielding effectiveness = 10 log (Pout / Pin), related to S12, and RE = Reflection Effectiveness = 10 log (Prefl / Pin), related to S11, in the UHF band (0.7 to 3GHz), of some polymer composites involving cadmium oxide (CdO), barium titanate (BaTiO3 = BT) and lead metaniobate (PbNb2O6 = PN). These data are directly printed by the Vector Network Analyzer, and designated here as “Experimental” result.

|

Sample name

|

Composite

Materials

|

Composition ratio

|

SE in dB at (Frequency in GHz)

|

RE in dB at (Frequency in GHz)

|

|

CdO_800 BT 34

|

PB:CdO_800:BT

|

1:0.371:0.185

|

-0.816 (3.000)

|

—

|

|

CdO_800 33= CdO_800 33I

|

PB:CdO_800

|

1:0.194

|

-0.644 (3.000)

|

-10.747(3.000)

|

|

CdO_800 33II

|

PB:CdO_800

|

1:0.194

|

-1.241 (3.000)

|

-7.198(3.000)

|

|

BT 31

|

PB:BT

|

1:0.434

|

-0.589 (3.000)

|

—

|

|

PN351

|

PB:PN

|

1:0.952

|

-1.0811 (3.000)

|

-9.8047 (3.000)

|

|

PN352

|

PB:PN

|

1:0.551

|

-1.4802 (3.000)

|

-9.4151 (3.000)

|

|

PN353

|

PB:PN

|

1:0.134

|

-0.9059 (3.000)

|

-10.450 (3.000)

|

Table 2: Shielding effectiveness (SE), giving direct experimental data as “Exp.” points and data from polynomial fit as “Fit” points, of polymer composites with conducting materials – fired cadmium oxide (CdO_firng temperature), Brass and Copper (Cu) in X band (8 to 12GHz). Each SE value is followed by frequency (in bracket) at which SE has been measured.

|

Sample name

|

Composite

Materials

|

Composition ratio

|

Sample thickness

(mm)

|

SE in dB at

(Frequency in GHz)

|

RE in dB at

(Frequency in GHz)

|

|

Exp.

|

Fit.

|

Exp.

|

Fit.

|

|

CdO_800 42

|

PB:CdO_800

|

1:1.447

|

2.05

|

-14.631

(9.590)

|

-13.953

(9.368)

|

-1.532

(9.609)

|

-1.482

(9.876)

|

|

-4.529

(11.609)

|

-4.529

(11.305)

|

-4.625

(11.605)

|

-5.216

(11.819)

|

|

CdO_RT

|

PB:CdO_RT

|

1:0.111

|

2.88

|

-6.205

(7.996)

|

|

-2.497

(8.005)

|

|

|

-1.905

(11.999)

|

-12.494

(11.826)

|

-12.707

(11.844)

|

|

CdO_270

|

PB:CdO_270

|

1:0.085

|

2.23

|

-4.880

(8.003)

|

-3.467

(8.012)

|

|

|

-0.950

(9.003)

|

-0.936

(8.902)

|

-17.232

(11.826)

|

-18.697

(11.864)

|

|

Brass 41

|

PB:Brass

|

1:0.485

|

3.58

|

-18.674

(8.396)

|

-15.446 (8.135)

|

-2.337

(8.403)

|

-1.984

(8.539)

|

|

27.276

(11.599)

|

27.371

(11.5)

|

-6.256

(10.806)

|

-6.899

(10.574)

|

|

Brass 23

|

PB:Brass

|

1:0.596

|

3.0

|

-1.350

(10.799)

|

-1.318

(10.713)

|

|

|

|

-4.167

(11.1979)

|

-5.019

(11.440)

|

|

Brass 24

|

PB:Brass

|

1:0.596

|

4.75

|

-3.653

(9.995)

|

-1.318

(10.713)

|

|

-1.350

(10.799)

|

-3.996

(11.367)

|

|

Cu 51

|

PB:Cu

|

1:0.497

|

2.19

|

-16.366

(9.580)

|

-17.560

(9.496)

|

|

-32.828

(10.38)

|

-28.564

(10.293)

|

Table 3: Shielding effectiveness (SE), giving direct experimental data as “Exp.” points and data from polynomial fit as “Fit” points, of polymer composites with dielectric materials – BaTiO3 (BT) and PbNb2O6 (PN) in X- band (8 to 12GHz). Each SE value is followed by frequency (in bracket) at which SE has been measured.

|

Sample name

|

Composite materials

|

Composition ratio

|

Sample thickness

(mm)

|

SE in dB at

(Frequency in GHz)

|

RE in dB at

(Frequency in GHz)

|

|

Exp.

|

Fit.

|

Exp.

|

Fit.

|

|

BT 26

|

PB:BT

|

1:0.314

|

6.0

|

-8.3492

(11.2043)

|

-8.8927 (11.3403)

|

-8.330

(11.191)

|

-8.901

(11.335)

|

|

BT 27

|

PB:BT

|

1:0.314

|

2.5

|

-3.8895

(8.4039)

|

-3.8895

(8.4039)

|

-3.897

(8.397)

|

-3.897

(8.397)

|

|

BT 27A

|

PB:BT

|

1:0.314

|

4.5

|

-7.2246

(8.3971)

|

-7.2246

(8.4856)

|

-7.225

(8.404)

|

-7.300

(8.479)

|

|

PN351

|

PB:PN

|

1:0.952

|

|

-0.763

(10.017)

|

|

-7.854

(8.396)

|

|

|

-1.075

(11.0004)

|

|

-8.249

(11.254)

|

|

PN351_2

|

PB:PN

|

1:0.952

|

|

-1.027

(10.017)

|

|

-18.911

(10.011)

|

|

|

-1.075

(11.0004)

|

|

-7.875

(11.254)

|

|

PN352

|

PB:PN

|

1:0.551

|

|

-0.358

(10.017)

|

|

-9.621

(9.806)

|

|

|

-2.551

(11.0004)

|

|

-6.134

(11.254)

|

|

PN352_2

|

PB:PN

|

1:0.551

|

|

-0.763

(10.017)

|

|

-6.789

(9.806)

|

|

|

-1.075

(11.0004)

|

|

-7.998

(11.254)

|

|

PN353

|

PB:PN

|

1:0.134

|

|

-0.358

(10.017)

|

|

-14.080

(9.806)

|

|

|

-4.98

(11.0004)

|

|

-4.425

(11.254)

|

|

PN353_2

|

PB:PN

|

1:0.134

|

|

-0.382

(10.017)

|

|

-9.983

(9.806)

|

|

|

-2.551

(11.0004)

|

|

-6.237

(11.254)

|

Table 4: Shielding effectiveness in the X band frequency range, giving direct experimental data as “Exp.” points and data from polynomial fit as “Fit” points, of a few composites of the polymeric binder and two additives.

|

Sample name

|

Composite

Materials

|

Composition ratio

|

Sample thickness

(mm)

|

SE in dB at (Frequency in GHz)

|

RE in dB at (Frequency in GHz)

|

|

Exp.

|

Fit.

|

Exp.

|

Fit.

|

|

CdO_800 BT 32

|

PB:CdO_800:BT

|

1:0.207:0.205

|

|

-3.243

(8.403)

|

—

|

-4.654

(8.997)

|

—

|

|

-10.033

(11.799)

|

-10.484

(11.905)

|

-3.065

(11.033)

|

|

|

CdO_800 BT 34

|

PB:CdO_800:BT

|

1:0.371:0.185

|

|

-9.276

(8.795)

|

-9.615

(8.605)

|

-1.083

(10.007)

|

-1.287

(10.007)

|

|

-29.714

(9.901)

|

-27.219

(9.965)

|

-3.909

(11.598)

|

-4.415

(11.799)

|

|

Brass CdO_800 43

|

PB:Brass :CdO_800

|

1:0.22:0.44

|

2.05

|

-13.360

(11.203)

|

-14.066

(11.382)

|

-14.408

(9.5096)

|

-14.882

(9.302)

|

|

—

|

—

|

-4.642

(11.1998)

|

-4.208

(11.438)

|

Conclusions

EMI shielding effectiveness and efficiency of some composite polymers, prepared using the conducting oxide power, CdO_800, non-conducting oxide powers, CdO_270 and CdO_RT, high dielectric constant (HDC) ferroelectric powder BaTiO3, medium (value) dielectric constant, MDC, ferroelectric powder PbNb2O6, metallic turnings of brass and copper from workshop waste, have been measured in UHF and X-band. In UHF band, BT (HDC), PN (MDC) and CdO_800 (conducting) based polymeric composites with single or multiple active materials, totaling seven samples, absorption and reflection power is very low – implying low shielding. Out of these seven poor shielding samples, PN352 shields best (transmitting ~ 71.1% at 3 GHz, compared to ~ 87.32% transmission for BT31. For conductive composites (CdO_800), reflection part increases (~ 10.64%) and absorption part remains practically unchanged (only ~ 0.43% change), on increasing thickness (CdO_800 33 sample, single to double layer change), to show reflection to be the dominating mechanism. For dielectric composites (PN35), on the other hand, reflection part changes little (~ 2.42% change only) and absorption part increases significantly (~ 7.46%), on increasing dielectric powder (PN) wt.% from 13.4 to 55.1. Transmission is much less in X- band than in UHF band implying better EMI shielding. For example, PN352 sample transmits 24.4% for single layer and ~ 15.7% for double layer at 11.256 GHz (X-band), whereas it has ~ 71.1% transmission at 3 GHz (UHF band). Also, absorption increases from ~ 17.5% (at 3 GHz, UHF) to ~ 26.2% (at 11.256 GHz, X-band). PN samples shield better than BT or BT_CdO samples in low frequency range (700 MHz to 3 GHz). Copper composite polymer samples act as better shielding materials (~ 0.05% transmitted at 10.3822 GHz) than brass composite polymer sample (1.01% transmitted at 10.3822 GHz), in 8 to ~ 10.83 GHz range. But, brass composite polymer sample shows better shielding (0.18% transmission at 11.600 GHz) performance than Cu composite polymer sample (1.12% at 11.600 GHz) above ~ 10.83 GHz – up to the highest frequency studied here (12 GHz). Low transmission i.e. good EMI shielding by these workshop waste materials (copper and brass turnings) has been possible by our fabrication of cloth-like polymeric composites with these materials, opening up a lower cost substitute for the widely used metal sheets and wire-meshes. The fabrication needs to be further perfected for optimum EMI shielding. Since the shielding mechanism for such composites is complex and not fully known, one has to depend more on experimentally found shielding data than on theoretical estimates, and also improve theory from extensive experimental data. Present EMI shielding measurements is a step in this direction.

EM emission is higher in high energy density devices so that above considerations of electromagnetic interference and shielding are more important for high energy materials. Applications involving intelligent materials are sensitive devices that are likely to be significantly affected by EM waves coming from the environment, needing protection by EM shielding.

Acknowledgments

The EMI shielding measurement set-up at SAMEER, Kolkata, India, has been used with the active encouragement of the scientist-in-charge Dipanker Dan and his groups.

References

- Akbaba M. and Gokdeniz M., Turkish Journal of Occupational /Environmental Medicine and Safety. 20151:1.

- Lewicka M., Henrykowska G. A., Pacholski K., Szczęsny A. Buczyńska M. D., and Buczyński A., Advances in Clinical and Experimental Medicine. 2015;24:31.

CrossRef

- Ajiboye Y., Farai P., Ayinmode B. O., and Alao O. A., IOSR Journal of Applied Physics. 2014;6:40.

- Rifai A. B., and Hakami M. A., Journal of Biosciences and Medicines. 2014;2:1.

- Dhami A. K., International Journal of Environmental Research. 2015;9:977.

- Joo J., and Epstein A. J., Applied Physics Letters. 1994;65:2278.

CrossRef

- DattaGupta N., Sahu K. R., and De U.,: Flexible EMI shielding-preparation and testing. 150th Birth Anniversary of Achararya J.C. Bose, International Symposium on Micrometer and Millimeter waves: Basics and Technology, January-2009, Bose Institute, Kolkata-700009, India, http://bic.boseinst.ernet.in/seminar/workshop/isomm2008.

- Kumar K. K. S., Geetha S., and Trivedi D. C., Current Applied Physics. 20055:603.

- Abbas S. M., Dixit A. K., Chatterjee R., and Goel T.C., Materials Science and Engineering: B. 2005;123:167.

CrossRef

- Hakansson E., Amiet A., and Kaynaka A., Synthetic Metals. 2006;156:917.

CrossRef

- Hakansson E., Amiet A., Nahavandi S., and Kaynak A., European Polymer Journal. 2007;43:205.

CrossRef

- De U., Sahu K. R., and DuttaGupta N., : Coating and Flexible Materials for Radar Absorption and EMI Shield. The 8th Int. Conf. on Advanced Polymers via Macromolecular Engineering 2009, Dresden, Germany, http://www.ipfdd.de/APME-2009.

- Liang J., Wang Y., Huang Y., Ma Y., Liu Z., Cai J., Zhang C., Gao H., and Chen Y., carbon. 2009;47:922.

CrossRef

- De U., Chaudhuri S. K., Sahu K. R., Das D., DuttaGupta N., and Chakraborty K. R., Physica Status Solidi C. 2009;6:2513.

CrossRef

- De U., Sahu K. R., Chakraborty K. R., and Pratihar S. K., Integrated Ferroelectrics. 2010;119:96.

CrossRef

- Verma K. C., and De U., Indian Journal of Physics. 2005;79:1975.

- Choi J. S., Kang Y. H., and Kim K. H., Journal of Physical Chemestry. 1977;81:2208.

CrossRef

- Celozzi S., Araneo R., and lovat G., John Wiley & Sons, Inc., Hoboken, New Jersey. 2008.

- Wada S., Yamato K., Pulpan P., Kumada N., Lee B. Y., Iijima T., Moriyoshi C., and Kuroiwa Y. Journal of Applied Physics. 2010;108:094114-1..

CrossRef

- Wada S., Takeda K., Muraishi T., Kakemoto H., Tsurumi T., and Kimura T., Japanese Journal of Applied Physics. 2007;46:7039.

CrossRef

- Sahu K. R., and De U., Journal of Materials. 2013;1.

- Kaynak A., Materials Research Bulletin. 1996;31:845.

CrossRef

- Mao Y., Mao S., Ye Z. G., Xie Z., and Zheng L., Materials Chemistry and Physics. 2010;124:1232.

CrossRef

- Sahu K. R., and De U., Thermochimica Acta. 2009;490:75.

CrossRef

- Sahu K. R., and De U., Thermochimica Acta. 2014;589:25-30.

CrossRef

- Dhawan S. K., Singh N., and Venkatachalam S., Synthetic Metals. 2002;129:261.

CrossRef

- DattaGupta N., Sahu K. R., Das I., De A., and De U., Indian Journal of Physics. 2010;84:1413.

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal

![Figure 5 Variation, in the range 0.7 to 3GHz, of EMI shielding effectiveness in transmittance mode of polymeric composite with BaTiO3 (BT 31 sample), with 800°C fired CdO (CdO_800 33 sample) and with a mixture of the two (CdO_800 BT 34 sample), adapted from [22].](http://www.materialsciencejournal.org/wp-content/uploads/2016/12/Vol13_No1_Sah_UHF_fig5-150x150.jpg)