Mechanical and Microstructure Properties on Al-Cu Joint processed by Friction Stir Welding: The Effect of Tilt Angle Tool

Jupri1,2* , Jon Affi2

, Jon Affi2 , Devi Chandra2, Mochamad Asrofi2,3

, Devi Chandra2, Mochamad Asrofi2,3

1Department of Mechanical Engineering, Bengkalis State Polytechnic, 28711, Bengkalis-Riau-Indonesia

2Department of Mechanical Engineering, Andalas University, 25163, Padang-Sumatera Barat-Indonesia

3Laboratory of Material Testing, Department of Mechanical Engineering, University of Jember, 68121, Jember-Jawa Timur-Indonesia

Corresponding Author E-mail: jup.ri11@yahoo.com

DOI : http://dx.doi.org/10.13005/msri/160108

Article Publishing History

Article Received on : 11-Jan-2019

Article Accepted on : 20-Feb-2019

Article Published : 25 Feb 2019

Plagiarism Check: Yes

Reviewed by: VINAYAGAMOORTHY R

Second Review by: Pavan Hiremath

Final Approval by: Manoj Gupta

Article Metrics

ABSTRACT:

The tilt angle tool on Aluminum A5083 and Copper C11000 joint processed by Friction Stir Welding (FSW) was observed in this study. The rotation speed and transverse speed were used as a parameter process for 2500 rpm and 30 mm/min, respectively. The tensile test and microstructure observation were carried out to determine the tensile strength and metal flow on Al-Cu joint, respectively. The result shows that the highest tensile strength was in 2o tilt angle tool for 105 MPa. Its fracture surface was more close to Al and formed brittle formation.The metal flows of Al-Cu with 0o and 2o were not homogeneous and formed an agglomeration of Cu particle to Al surface.

KEYWORDS:

Al-Cu Joint; Friction Stir Welding; Mechanical Properties; Microstructure; Tilt Angle

Copy the following to cite this article:

Jupri, Affi J, Chandra D, Asrofi M. Mechanical and Microstructure Properties on Al-Cu Joint processed by Friction Stir Welding: The Effect of Tilt Angle Tool. Mat.Sci.Res.India;16(1).

|

Copy the following to cite this URL:

Jupri, Affi J, Chandra D, Asrofi M. Mechanical and Microstructure Properties on Al-Cu Joint processed by Friction Stir Welding: The Effect of Tilt Angle Tool. Mat.Sci.Res.India;16(1). Available from: https://bit.ly/2tDYb10

|

Introduction

Friction stir welding is one part of solid welding and founded by The Welding Institute in 1991. FSW utilize the heat from friction the tool against the workpiece under the axial pressure of the weld area so as resulting the metal soften, mix and deform, but not the melting of metals.1,2

Material joining with different types of material such as Al-Cu using FSW produces intermetallic compounds welded joints.3-6 This case was different from fusion welding. In FW process the welded area easy to form the porosity, cracks, and defects on the sides of weld joints.7-9

Joining material with FSW requires several parameter processes to determine a result of the welding. The tool design can affect the mechanical properties and microstructure of welded joints between Al-Cu.10,11 In addition, another important parameter was the tool angle with slope range 0-3°, rotation speed tool and traverse speed during the FSW process.5, 12-17 Mohanty et al., reported that the influence of shoulder and pin probe diameter on the results of welded joints.18 Previous researchers also reported about pin geometry affects the metal flow behavior and strain distribution when the metal stirring process is on the advancing and reversing side.19-23 Threaded pins have the ability to produce and maintain continuous heat.24-26 Thus, affecting mechanical properties,27-29 and physical from welded joints.27,30

According to the best our knowledge, there is a little information about the effect of tool angle on Al-Cu joint processed by FSW. Therefore, the aim of this study was to know the mechanical and microstructural properties of Al-Cu joint fabricated by FSW. The tool material and the welded material were used tool steel H13 and Al A5083-Cu C11000, respectively.

Experimental procedure (Materials and Methods)

H13 tool steel was produced by means of the annealing process at 845-900° C and classified into chromium hot work steels due to there are carbide elements such as chromium and vanadium. H13 steel has the toughness and recommended as a tool material due to its resistance to high temperatures. The chemical composition of H13 steel can be seen in Table 1.31

Table 1: Composition limits for hot-work tool steels.31

|

AISI Type

|

UNS No.

|

Composition, wt %

|

|

C

|

Mn

|

Si

|

Cr

|

Ni

|

Mo

|

V

|

|

Chromium hot-work steel

|

|

H13

|

T20813

|

0.32-0.45

|

0.20-0.50

|

0.80-1.20

|

4.75-5.50

|

0.30 max

|

1.10-1.75

|

0.80-1.20

|

The aluminium alloy A5083 and Cu C11000 were used as a welded joint material. Aluminium was produced by means of annealing and in the heat treatment process was added 4.5% magnesium and 0.7% manganese. The addition of elements was to make tolerate ability, rolled ability, improve strength, wear resistance and extrusion.32 Table 2 shows the chemical composition of Al A5083. While the Cu C11000 material has 99% Cu content.33 The chemical composition of Cu C11000 can be seen in Table 3.

Table 2: Composition of wrought aluminium alloys.32

|

Grade

|

Composition, wt%

|

|

|

|

|

|

|

|

|

|

|

Unspecified other elements

|

Min

|

|

ASM

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

Ti

|

Each

|

Total

|

Al

|

|

A

5083

|

0.40-0.7

|

0.40

|

0.10

|

0.40-0.10

|

4.0-4.9

|

0.05-0.25

|

0.25

|

0.15

|

0.05

|

0.15

|

Rem

|

Table 3: Composition of copper.4

|

UNS No.

|

Composition, wt %

|

|

Zn

|

Pb

|

Ni

|

Al

|

Co

|

B

|

Sb

|

Nb

|

Others

|

Cu

|

|

C11000

|

0.137

|

<0.1

|

0.02

|

0.023

|

0.012

|

0.077

|

0.036

|

0.043

|

<0.492

|

Balance

|

FSW process was carried out by using a milling machine, the shape of the design tool was trapezoidal and butt-joint welded joints. The FSW joint material was Al A5083 and Cu C11000. The machining parameters and other parameters can be seen in Table 4. After the welding process then specimen was manufactured which refer to the ASTM E8 / E8M standard for tensile test,34 and ASM Metal Vol. 9 for microstructure tests.35

Table 4: Parameter process friction stir welding.

|

Parameter process

|

Values

|

|

Shape of tool

|

Trapezium

|

|

Pin length

|

3.7 mm

|

|

Pin (ᴓ)

|

4-5 d

|

|

Shoulder (ᴓ)

|

18 d

|

|

Rotation speed (N)

|

2500 rpm

|

|

Transverse speed(F)

|

30 mm/min

|

|

Tilt angle

|

0° and 2°

|

Tensile Properties

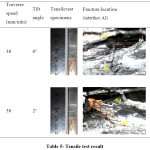

Table 5 shows the mechanical properties of butt-joint welded, wherein the process of Al-Cu joint, the parameters process used were 2500 rpm of spindle rotation speed, 30 mm / min of feeding speed and tool slope angle (0° and 2°). At the Al-Cu joint with a slope angle of 0° the location of the friction stir processed zone is more towards to Al, then on the fracture surface, there is a buildup of Cu particles and resulting 90 MPa.

While, Al-Cu joint with a slope angle of 2°, the fractured material location occurs in the friction stir processed zone area towards Al and Cu fractions attached and resulting 105 MPa. The fracture shape of the welded joint with a slope angle of 0° and 2° was brittle due to the shiny surface, there is no necking on the test specimen and extends to form a straight line from the weld joint. The lowest strength of the weld joint on 0° of slope angle due to the non-spread evenly of Al and Cu metal during friction stir welding in the processed zone.

Table 5: Tensile Test Result

Microstructure

Table 6 displays a microstructural image of welded joints with slope angles of 0° and 2°. Microstructure observations were seen through the side, namely top surface(friction stir processed zone.

The microstructure showed differences in the flow of Al-Cu metals. In FSW zone, the Al-Cu flow is not spread evenly due to slight displacement and shaped like a line. While, in the friction stir processed zone, the flow of Al-Cuis not evenly distributed, the transfer of Cu metal to Al is not evenly distributed along the mixing zone and the shape of the surface forms a little zigzag.

Table 6: Optical microscope observation.

Conclusion

Based on the result, we can conclude that:

- The highest tensile strength was in 2o slope angle for 105 MPa. This is due to a good Al-Cu flow during friction stir welding in friction stir zone.

- The microstructural observation showed an inhomogeneous of Al-Cu flow on all side of friction stir processed zone.

Acknowledgements and Funding Source

This research was funded by “LPDP (Indonesia Endowment Fund for Education) from the Ministry of Finance Indonesia with the project name “Master Thesis Research”. We also thanks to Ministry of Finance Indonesia for supporting my master study at Andalas University, Indonesia.

References

- Olson D. L., Siewert T. A., Liu S., and Edwards G. R. Welding, brazing and soldering, (1993) Vol. VI, ASM Handbook Committee, United States of America, 2873.

CrossRef

- Mishra R. S., Ma Z. Y. Friction stir welding and processing, Journal of Material Science and Engineering, (2005) Vol. 50, 1–78.

CrossRef

- Xue P., Xiao B. L., Ni D. R., Ma Z. Y. Enhanced mechanical properties of friction stir welded dissimilar Al-Cu joint by intermetallic compounds, Journal of Materials Science and Engineering, (2010) Vol. 527, No. 21–22, 5723–5727.

CrossRef

- Characterization of the intermetallic compounds in aluminum and copper friction stir spot welds, University of Johannesburg, Johannesburg, South Africa, Elsevier Ltd, (2017) Vol. 4, No. 2, 533–540.

- Esmaeili A., Rajani H. R. Z., Sharbati M., Givi M. K. B., Shamanian M. The role of rotation speed on intermetallic compounds formation and mechanical behavior of friction stir welded brass/aluminum 1050 couple, Journal of Intermetallics, (2011) Vol. 19, No. 11, 1711–1719.

CrossRef

- Galvão I., Oliveira J. C., Loureiro A., Rodrigues D. M. Intermetallics Formation and distribution of brittle structures in friction stir welding of aluminum and copper: Influence of shoulder geometry, Journal of Intermetallics, (2012) Vol. 22, 122–128.

CrossRef

- Liu P., Shi Q., Wang W., Wang X., Zhang Z. Microstructure and XRD analysis of FSW joints for copper T2/aluminium 5A06 dissimilar materials, Journal of Materials Letters, (2008) Vol. 62, No. 25, 4106–4108.

CrossRef

- Tavassoli S., Abbasi M., Tahavvori R. Controlling of IMCs layers formation sequence, bond strength and electrical resistance in Al–Cu bimetal compound casting process, Journal of Materials and Design, (2016) Vol. 108, 343–353.

CrossRef

- Liu H. J., Shen J. J., Zhou L., Zhao Y. Q., Liu C., Kuang L. Y. Microstructural characterization and mechanical properties of friction stir welded joints of aluminum alloy to copper, Journal of Science and Technology of Welding and Joining, (2011) Vol. 16, No. 1, 92–99.

CrossRef

- Mehta K. P., Badheka V. J. Influence of tool pin design on properties of dissimilar copper to aluminum friction stir welding, Journal of Transactions Nonferrous Metal, (2017) Vol. 27, No. 1, 36–54.

CrossRef

- Zhang Y. N., Cao X., Larose S., Wanjara P. Review of tools for friction stir welding and processing, Journal of Canadian Metallurgical Quarterly. (2012) Vol. 51, No. 3, 250–261.

CrossRef

- Omesh R., Dolas D. A review on tool materials, geometries and welding variables used for friction stir welding, Journal of Materials and Design, (2016) No. 3, 3870–3875.

- Mehta K. P., Badheka V. J. A review on dissimilar friction stir welding of copper to aluminum : process, properties, and variants, Journal of Material and Manufacturing Processes, (2016) Vol. 31, No. 3, 233–254.

CrossRef

- Xue P., Ni D. R., Wang D., Xiao B. L., Ma Z. Y. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints, Journal of Material Science and Engineering, (2011) Vol. 528, 4683–4689.

CrossRef

- Elangovan K., Balasubramanian V. Influences of pin profile and the rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminum alloy, Journal of Materials Science and Engineering, (2007) Vol. 459, 7–18.

CrossRef

- Muthu M. F. X., Jayabalan V. Tool travel speed effects on the microstructure of friction stir welded aluminum-copper joints, Journal of Materials Processing Technology. (2015) Vol. 217, 105–113.

CrossRef

- Shen J. J., Liu H. J., Cui F. Effect of welding speed on microstructure and mechanical properties of friction stir welded copper, Journal of Materials and Design, (2010) Vol. 31, No. 8, 3937–3942.

CrossRef

- Mohanty H. K., Mahapatra M. M., Kumar P., Biswas P., Mandal N. R. Effect of tool shoulder and pin probe profiles on friction stirred aluminum welds–a comparative study, Journal of Marine Science and Application, (2012) 200–207.

CrossRef

- Dialami N., Chiumenti M., Cervera M., Saracibar C. A. D., Ponthot J. P., Bussetta P. Numerical simulation and visualization of material flow in friction stir welding via particle tracing, Journal of Computational Methods in Applied Science, (2014) 157–169.

- Bussetta P., Dialami N., Chiumenti M., Saracibar C. A. D., Cervera M., Boman R., Ponthot J. P., 3D numerical models using a fluid or a solid formulation of FSW processes with a non-cylindrical pin, Journal of Adv Modeling Simulation in Engineering Science(2015).

- Dialami N, Chiumenti M., Cervera M., Saracibar C. A. D. An apropos kinematic framework for the numerical modeling of friction stir welding, Journal of Computers and Structures, (2013) Vol. 117, 48–57.

CrossRef

- Saracibar C. A. D., Chiumenti M., Cervera M., Dialami N., and Seret A. Computational modeling and sub-grid scale stabilization of incompressibility and convection in the numerical simulation of friction stir welding processes, Journal of Arch Computers and Methods Engineering, (2014) 3–37.

- Sun Z., Wu C. S. A numerical model of pin thread effect on material flow and heat generation in the shear layer during friction stir welding, Journal of Manufacturing Processes, (2018) Vol. 36, 10–21.

CrossRef

- Lammlein D. H. Computational modeling of friction stir welding, Journal of Literature Review, (1991) 1–36.

- Zhao Y. H., Lin S. B., Qu F. X., Wu L. Influence of pin geometry on material flow in friction stir welding process, Journal of Materials Science and Technology, (2006) Vol. 22,No. 1.

CrossRef

- Beygi R., Mehrizi M. Z., Verdera D., Loureiro A. Influence of tool geometry on material flow and mechanical properties of friction stir welded Al-Cu bimetals, Journal of Materials Processing Technology, (2018) Vol. 255, 739–748.

CrossRef

- Muthu M. F. X., Jayabalan V. Effect of pin profile and process parameters on microstructure and mechanical properties of friction stir welded Al−Cu joints, Journal of Transactions Nonferrous Metals, (2016) Vol. 26, No. 4, 984–993.

CrossRef

- Zhoa Y., Lin S., Wu L., Qu F. The influence of pin geometry on bonding and mechanical properties in friction stir weld 2014 Al alloy, Journal of Materials Letters, (2014) Vol. 59, No. 2005, 2948–2952.

- Hattingh D. G., Blignault C., Niekerk T. I. V., James M. N. Characterization of the influences of FSW tool geometry on welding forces and weld tensile strength using an instrumented tool, Journal of Materials Processing Technology, (2008) Vol. 203, No. 1–3, 46–57.

CrossRef

- Elangovan K., Balasubramanian V. Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminum alloy, Journal of Materials and Design, (2008) Vol. 29, 362–373.

CrossRef

- Roberts G.Krauss G. and Kennedy R., Tool steels, ASM International Handbook, (1998) Vol V, 1₋6.

- Cayless R. B. C., Alloy and temper designation systems for aluminum and aluminum alloys, ASM International Handbook Committee, Vol. II, Alcon Rolled Products Company, (1990) 15-28.

- Copper Development Association., Copper in architecture design, CDA Handbook Publication by Copper Development Association Inc, New York, A4050-04/16 (2016).

- ASTM International., Standard test methods for tension testing of metallic materials, United States, (2009) 1–27.

- ASM International., Metallography and microstructure, American Society for Metals Handbook Committee, Printed in the United States of America, ISBN 0₋87170₋007₋7 (1985).

This work is licensed under a Creative Commons Attribution 4.0 International License.

, Jon Affi2

, Jon Affi2 , Devi Chandra2, Mochamad Asrofi2,3

, Devi Chandra2, Mochamad Asrofi2,3

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal