Effect of Silica Fume Surface Treatment on Natural Fibres in Resisting Chloride Resistance in Concrete

M. Sivaraja*, S. Kandasamy¹ and M. Sudhakaran Pillai²

*Department of Civil Engineering, Kongu Engineering College, Perundurai, Erode - 638 052, India.

1Ariyalur Campus, Anna University, Tiruchirappali, India.

2Central Institute of Coir Technology, Coir Board, Bangalore, India.

DOI : http://dx.doi.org/10.13005/msri/070126

Article Publishing History

Article Received on : 10 Sep 2009

Article Accepted on : 25 Oct 2009

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

The natural fibre concrete may undergo a reduction in strength as a result of weakening of fibres by the combination of alkali attack and environmental loads. Silica fume slurry treatment is one of the best way to improve the durability of natural fibres in concrete. In this paper, fibre reinforced concrete with natural fibres such as coir and sugarcane baggase of as received condition and silica fume treated were cast at three volume fractions, 0.5%, 1.0% and 1.5% and tested to study the chloride resistance. This experimental program consists of determination of mass loss and strength deterioration against hydrochloric acid attack, rapid chloride penetration and . From the studies, 10 to 20% reduction due to hydrochloric acid attack and 15 to 25% reduction due to freezing and thawing were observed in concrete with as received natural fibres. Concrete with treated natural fibres showed a better resistance against all the durability effects.

KEYWORDS:

Natural fibres; Fibre reinforced concrete; Durability; Chloride attack

Copy the following to cite this article:

Sivaraja M, Kandasamy S, Pillai M. S. Effect of Silica Fume Surface Treatment on Natural Fibres in Resisting Chloride Resistance in Concrete. Mat.Sci.Res.India;7(1)

|

Copy the following to cite this URL:

Sivaraja M, Kandasamy S, Pillai M. S. Effect of Silica Fume Surface Treatment on Natural Fibres in Resisting Chloride Resistance in Concrete. Mat.Sci.Res.India;7(1). Available from: http://www.materialsciencejournal.org/?p=2284

|

Introduction

The distinctive properties of natural fibre reinforced concretes are improved tensile and bending strength, greater ductility, and greater resistance to plastic and restrained shrinkage cracking and hence improved impact strength and toughness.1-4 Besides its ability to sustain loads, natural fibre reinforced concrete is also required to be durable. Durability relates to its resistance to deterioration resulting from external causes as well as internal causes.5 Some studies have been conducted by researchers6-7 on the durability of natural fibres and the effect of corroded fibres on the strength of mortar. Coir fibres were found to retain higher percentages of their initial strength than all other fibres after the specified exposure in the various mediums. However, the durability of natural fibres can be improved in concrete by adopting surface treatments. One of the simplest and effective techniques proposed by the earlier researchers was immersion of fibres in silica fume slurry prior to incorporation in Ordinary Portland Cement matrix. Hence, this paper investigates the durability properties against chloride attack of natural fibre reinforced concrete having as received natural fibres and silica fume slurry treated natural fibres. The properties were studied and discussed in terms of Strength deterioration factor.

Experimental

Ordinary Portland cement of 43 grade, conforming to Indian standards is used for making concrete throughout the investigation. Specific gravity is one of the important parameters in concrete mix design which can be found using pycnometer. Specific gravity of cement is 3.15. Locally available river sand, with a specific gravity of 2.54 and fineness modulus of 2.58 was used as fine aggregate. Hand broken granite stones from local quarries were used as coarse aggregate in this investigation. Maximum size of coarse aggregate was limited to 20 mm and to increase the workability of concrete, 10–20 mm range of aggregate was used. The specific gravity of coarse aggregate used was 2.6. Fibres from locally available Coconut Coir and Sugarcane bagasse waste of a length 50 mm and rice husk of length 6 mm were neatly cut and shaved. Other properties of the natural fibres are shown in Table 1. The concrete mix was designed as per Indian standards to achieve a compressive strength of 20 MPa. Mix proportion used for the study was 1 : 1.38 : 3.06. A constant water cement ratio of 0.5 was used in all mixes. Coir, Sugarcane and Rice husk fibres at three volume fractions such as 0.5%, 1.0% and 1.5% were randomly mixed with concrete.

Table 1: Properties of natural fibres used

Table 2: Chemical Composition of Cement and Silica fume

54 numbers with 18 different mixes of cube specimens having 150 mm size for acid attack, cylindrical specimens having 51 mm thick and 102 mm nominal diameter for rapid chloride penetration test and prism specimens having 500 × 100 × 100 mm size for freezing and thawing were cast. Laboratory type mixer machine was used to mix the ingredients of concrete. To avoid balling effect of fibres, the following procedure was followed in casting. First, aggregates and cement were put and allowed to mix for one minute and water was added within two minutes. Then, fibres were uniformly dispersed throughout the mass with slow increment. Finally, concrete was allowed to mix for three minutes. All the specimens were well compacted using table vibrator. The specimens were demoulded after one day and then placed in a curing tank for 28 days of curing. For 12 h prior to the testing, the specimens were allowed to air dry in laboratory. Since workability is a very sensitive parameter in fibre reinforced concrete, both slump and vee-bee tests were conducted to measure the workability of mix. The cast specimens were subjected to different environmental exposures and tested for mechanical strength properties.

Test Methods Acid Attack

Chloride attack is the term used to describe a series of chemical reactions between chloride ions & the components of hardened concrete principally cement paste, caused by exposure of concrete to moisture.8-9 Cube specimens of 150 mm size were cast for conventional concrete and natural fibre reinforced concrete and cured for 28 days. All concrete specimens were immersed in chloride solutions for 2 years. The specimens were positioned so that all sides were in contact with the solutions. A non-porous container is selected and chloride solution has been prepared by adding 5 % of concentrated HCl acid to 50 litres of distilled water. The pH of the solution was regularly monitored and adjusted to keep them constant. The performance of concrete was made based on the assessment of mass loss and strength deterioration factor. Strength deterioration factor is defined as the ratio of change in compressive strength to initial compressive strength. Test for compressive strength was carried out at room temperature and as per the Indian standards. The tests were carried out in a PC controlled compression testing machine.

Rapid Chloride Penetration Test

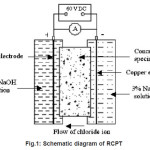

Rapid chloride penetration test (RCPT) was performed as per ASTM C 1202 to determine the electrical conductance of the natural fibre reinforced concrete mixes at the age of 28 days curing and to provide a rapid indication of its resistance to the penetration of chloride ions. The test method consists of monitoring the amount of electrical current passed through 51 mm thick slices of 102 mm nominal diameter of cylindrical specimens for duration of six hours. The test set up for RCPT is shown in Fig.1.10-11 The RCPT apparatus consists of two reservoirs. The specimen was fixed between two reservoirs using an epoxy bonding agent to make the test set up leak proof. One reservoir (connected to the positive terminal of the DC source) was filled with 0.3 N sodium hydroxide solution and the other reservoir (connected to the negative terminal of the DC source) with three percent sodium chloride solution. A DC of 60 V was applied across the specimen using two stainless steel electrodes (meshes) and the current across the specimen was recorded at 30 minutes interval for duration of six hours. The total charge passed during this period was calculated in terms of coulombs using the trapezoidal rule (ASTM C 1202),12

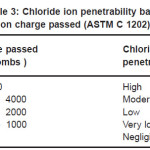

Where, Q, charge passed in coulombs and Io, current in amperes immediately after voltage is applied. The concrete quality (degree of chloride ion penetrability) can be assessed based on the limits as given in ASTM C 1202 (Table.3).

Figure 1: Schematic diagram of RCPT

Figure 2: Experimental set up for RCPT

Table 3: Chloride ion penetrability based on charge passed (ASTM C 1202)

Results and Discussion

Acid Attack

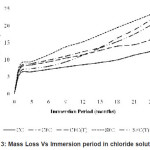

Fig.3 and Fig.4 show the results of resistance against chloride attack of conventional, coir fibre reinforced and sugarcane fibre reinforced concrete specimens. Average values of three specimens are given in the figures. Mass loss in conventional concrete at 30 days immersion obtained was 6%. This value was increased as 8.6% and 12.5% at one year and two years immersion periods. While coir reinforced concrete was considered, the mass loss was 7.8%, 12.4% and 22% for 30 days, one year and two year immersion periods. The higher mass loss was obtained in sugarcane baggase reinforced concrete specimens such as 8.5%, 15.3% and 23.5% for 30 days, one year and two years immersion periods respectively. Increase in weight loss obtained in natural fibre reinforced concrete specimens showed the possibility of decay in natural fibres. While concrete specimens with silica fume treated natural fibres are considering, coir fibre reinforced concrete showed mass loss as 7.4%, 11.5% and 16% respectively at 1 month, 1 year and two years immersion periods. Similarly silica fume treated sugarcane fibre reinforced concrete specimens exhibited the mass loss of 6.5%, 11.4% and 20.4% at immersion period of 1 month, 1 year and 2 year respectively. Hence it is evident that surface treatment of natural fibres with silica fume slurry reduced the weight loss in the range of 18% to 43% for coir fibre reinforced concrete and 23% to 13% for sugarcane fibre reinforced concrete.

Figure 3: Mass Loss Vs Immersion period in chloride solution

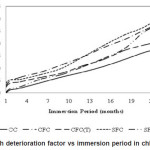

Figure 4: Strength deterioration factor vs immersion period in chloride solution

Compression strength deterioration factor for conventional, coir fibre reinforced, sugarcane fibre reinforced concrete cube specimens showed the similar pattern of degradation as mass loss. Strength deterioration of conventional concrete was obtained as 10%, 18.4% and 28.6% at the immersion period of 30 days, one year and two years respectively. Coir fibre reinforced concrete possessed 13%, 24.6% and 39.5% deterioration in compressive strength at the immersion period of 30 days, one year and two years. Similarly, the highest deterioration was obtained in sugarcane fibre reinforced concrete as 14%, 24.6% and 42.5% respectively for 30 days, one year and two years immersion period. Decrease in compressive strength of natural fibre reinforced concrete specimens due to chloride solution attack might be happened due to the damage of natural fibres due to acid attack. Silica fume treatment over the surface of natural fibres reduced the strength deterioration due to acid attack. Silica fume treated coir fibre reinforced concrete exhibited strength deterioration factors as 12.5%, 21% and 31.4% at 1 month, 1 year and 2 years immersion periods respectively, which were 4%, 15% and 20% lower than that of without treatment. Similarly in sugarcane fibre reinforced concrete, treated specimens possessed the strength deterioration values as 10.4%, 20.6% and 38.5% at 1 month, 1 year and 2 years immersion periods respectively, which were 25%, 16% and 10% lower than that of without treated specimens.

Rapid Chloride Penetration

Table.4 shows the percentage mass gain, rapid chloride penetration values and corresponding degree of penetrability of conventional concrete, natural fibre reinforced concrete with and without treatment. Mass loss in percentage gives an indication about the amount of chloride penetrated in to concrete. Mass loss obtained in conventional concrete 1.9%. The corresponding rapid chloride penetration (RCPT) value obtained in terms of charges passed was 2560 coulombs. Chloride penetration was similar in fibre reinforced concrete specimens also. The mass loss and the corresponding RCPT value obtained were 1.87%, 1.91% and 2640 coulombs, 2620 coulombs in coir and sugarcane fibre reinforced concrete specimens respectively. The degree of penetrability (according to ASTM C 1202) in these three concrete were moderate. Addition of silica fume treated natural fibres reduced the chloride ion penetration in concrete significantly. Mass loss obtained in coir and sugarcane fibre reinforced concrete specimens were 1.52% and 1.64% respectively. These values were 18% and 15% smaller than that of fibre reinforced concrete without treatment. Similarly, RCPT values obtained for concrete with treated coir and sugarcane fibres were 1650 coulombs and 1680 coulombs respectively. These values are around 35% smaller than that of concrete with as received natural fibres.

Conclusion

To study the effect of silica fume slurry treatment over surface of natural fibres such as coir and sugarcane baggase on durability of concrete in terms of chloride resistance, two experiments were conducted. From acid attack and rapid chloride penetration tests, the following conclusions are drawn. Although the addition of silica fume treated natural fibres in concrete reduced the loss of mass moderately (around 7%) at the initial period like one month, the effectiveness was higher (20%) in later period like 2 years. And the difference in mass loss between concrete with as received natural fibres and silica fume treated natural fibres obtained was in the range of 15% to 40%. Compressive strength deterioration against chloride solution attack was significantly reduced by addition of silica fume treated natural fibres instead of as received natural fibres. The difference observed was also in the range of 10% o 40%. The effectiveness observed from the RCPT also showed the benefit of addition of silica fume treated natural fibres in concrete rather than as received natural fibres. The difference in performance observed during RCPT was around 35%. Hence silica fume treatment on natural fibres such as coir and sugarcane not only enhanced the durability against chloride attack of fibes but also of concrete mass.

Acknowledgements

The authors gratefully acknowledge the financial support extended by the Coir Board (Ministry of Agro and Industries, Govt. of India) to carry out this research project.

References

- Al-Oraimi S.K and Seibi A.C., Comp Struct., 32: 165 (1995)

CrossRef

- Romildo D. Toledo Filho., Cem. Concr. Comp., 27: 537 (2005)

- Sivaraja M and Kandasamy S., Int J Mat Prod Tech., 136: 385 (2009)

CrossRef

- Sivaraja M and Kandasamy S., Reinf Plast Comp., 27: 135 (2008)

CrossRef

- Ramakrishna G and Sundararajan T., Cem Concr Comp., 27: 547 (2005)

CrossRef

- Romildo D. Toledo Filho, Khosrow Ghavami, George L. England and Karen Scrivener., Cem Concr Comp., 25: 185 (2003)

- Agopyan V, Savastano Jr, John V. M And Cincotto M. A., Cem Concr Comp., 27: 527 (2005)

CrossRef

- Murthi P and Sivakumar V., Asian J Civil Engg (Building and Housing)., 9: 473 (2008)

- Bai J, Wild S and Sabir Bb., Cement and Concr Res, 3: 353 (2003)

CrossRef

- Murthi P and Sivakumar V., Journal of Applied Engineering research., 3: 1481 (2008).

- S.Thirumoorthy, Experimental investigation on properties of concrete using lime sludge from sugar industry, M.E Thesis, Kongu Engineering College, Anna University, Chennai, India (2007).

- ASTM C1202 – 09, Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration, ASTM International, West Conshohocken, PA, 2003, DOI: 10.1520/C0033-03.

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal