Effect of Split Injection Concept on Emission Levels of Oxygenated Diesel Operated CI Engine

M. Kumaresan* and G. Devaradjane

1Department of Automobile Engineering, SACS M.A.V.M.M Engineering College, Kidaripatty, Madurai - 625 301, India.

2Department of Automobile Engineering, Anna University, MIT campus, Chennai, India.

DOI : http://dx.doi.org/10.13005/msri/070121

Article Publishing History

Article Received on : 01 Jan 2010

Article Accepted on : 01 Feb 2010

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

An experimental investigation has been carried out to understand the effect of split injection concepts on the emission level particularly on the reduction of Nitrogen oxide emission is accompanied with the reduction of Brake thermal efficiency, hence to offset the reduction of thermal efficiency blend of diesel and oxygenated compound Di-ethylene glycol have been used as fuel for the analysis.Thus the emission characteristics of diesel- Di-ethylene glycol are investigated using the single cylinder direct injection naturally aspirated diesel engine using split injection method involving double lobed cams. The double lobed cam was designed to inject fuel in the proportion of 40-60% with an interval of 8Ú between pilot and main injection. The oxygenated compounds Di-ethylene glycol is blended with diesel fuel in the proportion 5% and 7% by volume. The engine was tested using Eddy current dynamometer at a speed of 1500 r.p.m from no load to full load using diesel, 5% and 7% diesel-Diethylene Glycol blend using single injection and split injection. The AVL smoke meter and krypton gas analyzer are used for measuring emission parameters values. The emission curves such as CO, CO2, HC, NOx and smoke with respect to brake power are plotted for both single injection and single injection and compared. From the results, it is found that NOx emission is drastically reduced with split injection using diesel but slightly higher with diesel- Di-ethylene Glycol blend.

KEYWORDS:

Diesel engine; Single injection; Split injection; Double lobed cam; Oxygenated compound blends; Emission parameters.

Copy the following to cite this article:

Kumaresan M, Devaradjane G. Effect of Split Injection Concept on Emission Levels of Oxygenated Diesel Operated CI Engine. Mat.Sci.Res.India;7(1)

|

Copy the following to cite this URL:

Kumaresan M, Devaradjane G. Effect of Split Injection Concept on Emission Levels of Oxygenated Diesel Operated CI Engine. Mat.Sci.Res.India;7(1). Available from: http://www.materialsciencejournal.org/?p=2267

|

Introduction

A lot of extensive research is in progress to reduce both nitrogen oxides (NOx) and particulate (soot) emissions from diesel engines due to environmental concerns. One of the emission control strategies is in-cylinder reduction of pollutant production. It is well known that it is very difficult to reduce both NOx and soot production simultaneously during the combustion process. Many emission-reduction technologies developed so far tend to increase soot emission while reducing NOx emission, and vice versa. For example, retarding fuel injection timing can be effective to reduce NO formation. However, this usually results in an increase of soot emissions; it can also cause higher NOx emissions at the same time. Recently, it has been shown experimentally that with high pressure multiple injections, the soot–Nox trade-off curves of a diesel engine can be shifted closer to the origin than those with single pulse injections, reducing both soot and NOx emissions significantly.

Nehmer and reitz experimentally investigated the effect of double –pulse split injection on soot and NOx emissions using a single-cylinder caterpillar heavy-duty diesel engine. They varied the amount of fuel injected in the first injection pulse from 10 percent to 75 percent of the total amount of fuel and found that split injection schemes reduced NOx with only a minimal increase in soot emissions and did not extend the combustion duration.

Tow et al continued the study of Nehmer and Reitz using the same engine, and included different dwells between injection pulses and triple injection schemes in their investigation. They found that at high engine load (75%) particulate could be reduced by a factor of three with a relatively long dwell between injections. They also found that triple injections could reduce NOx and soot emissions at both light and high loads. Another important conclusion of tow et al. is that the dwell between injection pulses is very important to control soot production and there exits an optimum dwell at a particular engine operating condition. The optimum dwell of a double-injection was found to be about 10 degree crank angles at 75% load and 1600 rev\min for their engine conditions.

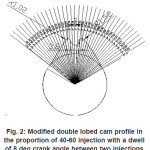

In this investigation the emissions characteristics are evaluated using the diesel- 5%, 7% by volume oxygenated compound Diethylene glycol blend in single cylinder diesel engine using split injection method involving double lobed cams. Split injection method is used for control of nitric oxide. In split injection, the injection of fuel is divided into two steps, the pilot injection of small quantity and main injection of large quantity with dwell between two injections the pilot injection is used to shorten the ignition delay and to control the rapid pressure rise.

Oxy Generated Compounds

Among 71 oxygenates obtained by literature survey, considering many aspects like cost oxygen content, flash point, solubility, availability, toxicity, lubricity, biodegradability Diethylene Glycol is selected for study. The selected oxygenate is blended with diesel fuel in proportion 5% and 7% by volume and experimental study is conducted in a single cylinder natural aspirated Direct injection diesel engine.

Structure of Oxygenated Compound

The chemical structure of Diethylene Glycol is shown below.

Diehtylene glycol (C4H10O3)

HOCH2CH2OCH2CH2OH

CAM Details

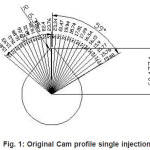

Single injection is achieved using the original fuel cam

Experimental

The emission test was conducted in a single cylinder naturally aspirated direct injection diesel engine with an eddy current dynamometer,The emission parameters such as CO, CO2, HC, NOx, . Smoke levels are measured and plotted w.r.to brake power using both single injection and split injection using diesel and 5%, 7% by volume Di-ethylene Glycol- diesel blend. The combustion analyzer, AVL Smoke meter and Krypton gas analyzer were used for this purpose and the engine is run at a constant speed of 1500 rpm.

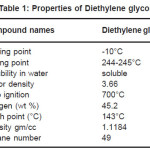

Table 1: Properties of Diethylene glycol

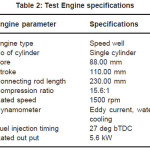

Table 2: Test Engine specifications

Results and Discussion

The emission parameter values for both single injection and split injection with diesel and diesel blends of 5% and 7% of Diethylene Glycol from no load to full load conditions with injection timing of 27degree BTDC are found and harmful pollutants such as CO, CO2, HC, NOx and smoke are plotted and compared.

It is found that at higher loads, for diesel, the Nitrogen oxides346ppm using single injection method and 240ppm using split injection method. For oxygenated blends at higher loads the 7% DEG gives 245ppm of NOx reduction

Effect of Smoke for Diesel and 5% And 7% Oxygenated Compounds Blends

It is found that at higher loads, for diesel, the Smoke is 41.4% using single injection method and 59.7% using split injection method.

For oxygenated blends at higher loads the 5% DEG gives 40.5% of Smoke reduction

Effect of Hydrocarbon for Diesel and 5% And 7% Oxygenated Compounds Blends

It is found that at higher loads, for diesel, the Hydrocarbon is 86ppm using single injection method and 92ppm using split injection method.

For oxygenated blends at higher loads the 5% DEG gives 86ppm of Hydrocarbon reduction.

Effect of Carbon-Monoxide for Diesel and 5% and 7% DEG Blends

It is found that at higher loads, for diesel, the carbon-monoxide is 0.07% by volume using single injection and 0.08% by volume using split injection.

For oxygenated blends at higher loads the 5% DEG gives 0.05% by volume of CO reduction.

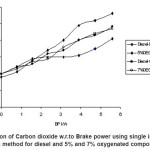

Effect of Carbon Dioxide for Diesel and 5% and 7% Oxygenated Compounds Blends

It is found that at higher loads, for diesel, the carbon-dioxide is 4.8% by volume using single injection method and 4.1% by volume using split injection method.

For oxygenated blends at higher loads the 7% DEG gives 4.7% by volume of CO2 reduction.

Figure 1: Original Cam profile single injection

Figure 2: Modified double lobed cam profile in the proportion of 40-60 injection with a dwell of 8 deg crank angle between two injections

Figure 3: Variation of nitrogen oxides w.r.to Brake power using single injection and split injection method for diesel and 5% and 7% oxygenated compounds blends

Figure 4: Variation of Smoke w.r.to Brake power using single injection and split injection method for diesel and 5% and 7% oxygenated compounds blends.

Figure 5: Variation of Hydrocarbon w.r.to Brake power using single injection and split injection method for diesel and 5% and 7% oxygenated compounds blends

Figure 6: Variation of Carbon-monoxide w.r.to Brake power using Single injection and split injection method for diesel 5% and 7% oxygenated compounds blends

Figure 7: Variation of Carbon dioxide w.r.to Brake power using single injection and split injection method for diesel and 5% and 7% oxygenated compounds blends

Conclusion

From the investigation it is found that with diesel at higher loads the NOx emission is reduced by about 30% with split injection, at the same load in the case of oxygenated blends the reduction of NOx is slightly higher with 5% by volume blend

Acknowledgements

This research work was done as a requirement for the award of Doctorate degree and it was done at MIT, Chennai, India under the guidance of Dr.G.Devaradjane.

Symbols and Nomenclature

DEG–Diethyl glycol; HC–Hydrocarbon; CO–Carbon monoxide; CO2–Carbon dioxide; NOx–Nitrogen Oxides; R–Radius of cam profile; deg–degree; rpm–revolution per minute; BTDC–before top dead centre; ppm–parts per million; BP–brake power; O(original cam)–single injection; M(modified cam)–split injection.

References

- A. K. Babu, and G. Devaradjane “Control of Diesel Engine Pollutants by Split Injection Method Using Multizone Model”, 2001-28-0007 (2001).

- Zhiyu Han, Ali Uludogan, Gregory J.Hamson and Rolf D. Reltz “Mechanism of Soot and NOx Emission Reduction Using Multiple-Injection in a Diesel Engine”, SAE paper 960633 (1996).

- T.C.Tow, D.A.Plerpont and R. D. Reltz “Reducing Particulate and NOx Emissions by Using Multiple Injections in a heavy duty D.I. Diesel Engine”, SAE paper 940897 (1994).

- G.Devaradjane “Effect of split injection on diesel engine pollutants using multi-zone model”., Indian journal of engineering and material sciences, 8: 129-135 (2001).

- D.A . Nehmar and R. D. Reltz “Measurement of the Effect of Injection Rate and Split Injections on Diesel Engine Soot and NOx Emissions”, SAE paper 940668 (1994).

- Charles J.Muller, William J.pitz and etal “Effects of Oxygenates on Soot Processes in D.I. Diesel Engines: Experiments and Numerical Simulations”, SAE paper 2003-01-1791 (2003).

- Gideon Goldwine, Eran Sher “Experimental investigation of effect split injection on diesel engine performance”, 50(1-4): 66-90 (2009).

- Jeffrey Hood, Robert Farina “Emission from light duty vehicle operating on oxygenated fuels at low ambient temperature”., SAE Paper 952403, (1995).

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal