Experimental Analysis on the Blends of Oxygenated Fuels with Diesel in A Direct Injection Diesel Engine for Performance Evaluation and Emissions

M. P. Sudeshkumar1* and G. Devaradjane2

1Department of Mechanical Engineering, Hindustan University, Padur, Chennai - 603 103, India.

2Department of Automobile Engineering, MIT Campus, Anna University, Chennai, India.

DOI : http://dx.doi.org/10.13005/msri/070130

Article Publishing History

Article Received on : 25 Feb 2010

Article Accepted on : 28 Mar 2010

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

Rapid depletion of petroleum reserves and the environmental pollution caused by the growing use of conventional fuels created a challenge before the world that new type of fuels should replace the conventional fuels to achieve the future emission regulations. Hence great deal of research effort has been focused to find alternative fuel. The consideration of oxygenates with diesel fuel is a recent approach receives great attention in reducing the exhaust emissions of an engine The combustion, performance and emission characteristics of diesel fuel and oxygenated blends with diesel are analyzed in a four stroke naturally aspirated single cylinder direct injection compression ignition engine. The additives include 2-Ethoxyethanol (2EE), DiethyleneGlycol Dimethyl ether (DGM) and 2-Methoxyethanol (2ME) and the oxygenated compounds were selected based on the availability, price and oxygen content. These oxygenated compounds are blended with diesel fuel in proportion of 6% by volume. Combustion parameters such as in-cylinder pressure and Heat release rate were studied. The engine emission characteristics of the Compression ignition (CI) engine fuelling with oxygenated blends are studied experimentally. The performance of oxygenates on thermal efficiency and specific fuel consumption were studied. Comparing the combustion, performance and emission, the addition of 2-methoxy ethanol blend shows better performance than other two oxygenated blends with diesel and diesel fuel.

KEYWORDS:

Combustion; Diesel engine; Emission; Oxygenated blend; Performance

Copy the following to cite this article:

Sudeshkumar M. P, Devaradjane G. Experimental Analysis on the Blends of Oxygenated Fuels with Diesel in A Direct Injection Diesel Engine for Performance Evaluation and Emissions. Mat.Sci.Res.India;7(1)

|

Copy the following to cite this URL:

Sudeshkumar M. P, Devaradjane G. Experimental Analysis on the Blends of Oxygenated Fuels with Diesel in A Direct Injection Diesel Engine for Performance Evaluation and Emissions. Mat.Sci.Res.India;7(1). Available from: http://www.materialsciencejournal.org/?p=2299

|

Introduction

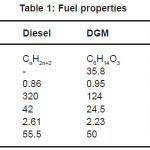

There is a need for alternative fuel to diesel engines due to increase in petroleum prices, depletion of petroleum oils and stringent emission norms. Oxygenated fuel is one of the prominent alternative fuels due to its availability and oxygen content receives much attention owing to increasing emission standards. Oxygenated fuels can be either synthetically prepared oxygenates or biomass products.1 Oxygenated fuels are made from synthesis gas which can be produced from both fossil and renewable raw materials. Oxygenated synthetic fuels are characterized by the following molecular conditions of the fuels: Molecular weights are low and the molecules have high hydrogen to carbon ratios and a low number of carbon to carbon bonds which lower the formation of solid carbon particulates. Molecules contain oxygen which suppresses the formation of soot. Molecular bonds break up to radicals at reasonable activation energy which leads to high cetane numbers.2 Many research studies indicated that an oxygen content of 7% by volume in fuel would be required to have 40% reduction in smoke and particulate emissions. Various oxygenates have been considered for use in diesel fuel based on their availability, price, toxicity, compatibility with diesel fuel and safety.3 Many researchers have investigated the effects of oxygenated compounds on performance and emissions in a diesel engine.4-9 Sirman et al. 10 published results of the effects of various alternative fuels on emissions from an advanced automotive diesel engine. Among the fuels tested was a blend of 15% DMM in a diesel fuel. They found that DMM produced substantial reductions in particulate emissions of 52% and in NOx of 4%. Although a great deal of research has been done on oxygenated compounds, it is still unclear to choose or predict which oxygenates might be most effective. Oxygenated fuels provide a viable alternative to diesel, as they are easily available. In the present work, diesel combustion, performance and exhaust emissions are investigated with the addition of three oxygenated blends with diesel fuel. The properties of diesel fuel, DGM, 2EE and 2ME were presented in Table 1.

Table 1: Fuel properties

Materials and Methods

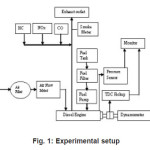

The test engine used for the present investigation is a single cylinder, 4-stroke, water cooled and naturally aspirated direct injection compression ignition engine. The loading of the engine is done by eddy current Dynamometer. The technical specifications of the engine are shown. The engine is of constant speed (1500 rpm) type with a fluctuation of ± 25 rpm. Time taken for 50 cc of fuel consumption was measured with the aid of burette and stop watch arrangement. Krypton 290 EN2 gas analyzer was used to measure the concentration of Carbon monoxide, Hydrocarbon, and Oxides of nitrogen. Smoke levels were measured using a standard smoke meter in Bosch Smoke unit. The combustion pressure was measured using pressure sensor in the cylinder head and the crank angle is obtained to a minimum scale reading of 1° for crank angle. Three readings are taken at each stage to ensure accuracy and the average value is recorded. All the measurements were recoded for 6% blending level of three oxygenated compounds. Fig.1 shows the schematic outline of experimental setup. Initially engine tests were performed using diesel fuel for all engine loads followed by oxygenated blends to measure the combustion, performance and pollutant emissions.

Figure 1: Experimental setup

Results and Discussion

Combustion Characteristics

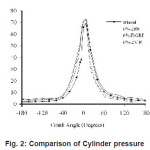

Peak Pressure

Peak pressure depends on the combustion rate in initial stages, which in turn influenced by the amount of fuel taking part in the uncontrolled combustion phase in a CI Engine. Fig. 2 shows the comparison of cylinder pressure with respect to crank angle for the engine running with diesel and the blends of oxygenated compounds at 80% load. It can be seen that the peak pressure is slightly higher for 2-ME blend when compared to that of diesel fuel due to improved burning rate. Addition of 2EE blend and DGM blend increases the cylinder pressure during premixed combustion phase and the pressure is slightly reduced in the diffusion phase of combustion due to change of state from molecular oxygen to atomic oxygen. The peak pressure is 69 bar, 72 bar, 73 bar and 73 bar for diesel, 2EE blend, DGM blend and 2ME blend with diesel fuel respectively. Results showed that oxygenated fuels are helping the premixed phase reactions to progress in a better way leads to better combustion.

Figure 2: Comparison of Cylinder pressure

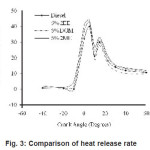

Heat Release Rate

The heat release rate for 6% 2-EE blend, 6% DGM blend, 6% 2-ME blend and diesel fuel at 80% load is shown in Fig.3. The peak heat release rate for diesel is 40 J/ °CA, for 2EE Blend it is 43 J/ °CA, for DGM Blend it is 43 J/ °CA and for 2ME blend is 44J/ °CA respectively. It is observed that peak heat release rate is higher for 2ME blend compared to other blends and diesel fuel due to improved ignition characteristics of the fuel. It was found from the results that heat release rate increases during initial part of combustion and then decreases when compared to that of diesel by the addition of 2EE blend and DGM blend due to slower combustion rates of blend.

Figure 3: Comparison of heat release rate

Performance Characteristics

Brake Thermal Efficiency

Fig.4 shows the comparison of Brake thermal efficiency (BTE) with respect to brake power for diesel and oxygenated blends. Increase in thermal efficiency was observed with all the three oxygenated blends. Due to better combustion of the oxygenated blends engine thermal efficiency have moderate improvement. The maximum Brake thermal efficiency of the engine with 2ME blend is 34% which is 10% higher than that of diesel engine. From the experimental results it was observed that the effect of 2ME blend with diesel fuel on thermal efficiency is remarkable. The Brake thermal efficiency of 2EE blend lie between those of 2ME blend and DGM blend.

Figure 4: Comparison of brake thermal efficiency

Brake Specific Fuel Consumption

Fig. 5 indicates the comparison of Specific fuel consumption with respect to brake power for diesel and oxygenated blends with diesel at a constant speed of 1500 rpm. The specific fuel consumption is found to be reduced for all the three oxygenated fuels. Due to better combustion of the fuel the specific fuel consumption have moderate improvement. From the experimental results it was observed that 2EE blend is more effective in reducing the fuel consumption than other two oxygenates and diesel fuel. The Specific fuel consumption at full load is 0.29 kg/kWh (diesel), 0.26 kg/kWh (2EE Blend), 0.27 kg/kWh (DGM Blend), and 0.28 kg/kWh (2ME Blend) respectively. Minimum brake specific fuel consumption (0.22 kg/ kWh) was obtained at a brake power of 4 kW for 2EE blend with diesel fuel.

Figure 5: Comparison of Specific fuel consumption

Emission Characteristics

CO Emissions

Carbon monoxide (CO) emissions are greatly dependant on the air fuel ratio relative to stoichiometric proportions. The comparison of CO emissions with different brake power output for diesel and oxygenated blends with diesel is shown in Fig.6. Addition of all the three oxygenated blends with diesel reduces carbon monoxide emissions from zero load to full load compared to diesel fuel. Reductions in the carbon monoxide emissions is due to improved combustion process since the oxygen content in the oxygenated blends with diesel fuel causes better combustion. 2ME blend with diesel reduces carbon monoxide emissions considerably compared to other blends with diesel fuel. The CO emission is approximately 20% less in case of 2ME blend compared to diesel fuel due to the presence of oxygen in the fuel leads to better combustion.

Figure 6: Comparison of Carbon monoxide emissions

HC Emissions

Unburnt hydrocarbon emissions consist of fuel that is incompletely burnt. The unburnt hydrocarbon emissions of three oxygenated blends are compared with diesel is shown in Fig. 7. Addition of DGM and 2EE blends with diesel reduces HC content in the exhaust compared to diesel. HC emission reductions may be attributed to better combustion. 2ME blend with diesel increases HC emissions. At full load, 2ME blend emits 113 PPM of HC emissions compared to 110 PPM of diesel fuel. Fine fuel spray which reduces momentum of droplets resulting in less complete combustion causes increase in HC emissions with 2ME blend with diesel fuel. 2EE blend with diesel shows better improvement in reducing HC emissions compared to other two blend proportions with diesel.

Figure 7: Comparison of Hydrocarbon emissions

NOx Emissions

Formation of NOx is dependent on cylinder temperatures; oxygen concentration etc. Fig.8 shows the comparison of NOx with respect to brake power for diesel and ignition improver blends. It is observed that addition of DGM and 2EE blends increases NOx emissions compared to diesel. Increase of NOx for oxygenated blends may be associated with the oxygen content and the oxygen present in the fuel may provide additional oxygen for NOx formation. Marginal increase in NOx emissions was observed with the addition of 2ME blend compared to other two oxygenated blends and diesel fuel. Since 2ME blend shows better impact than other two oxygenated blends 2ME Blend can be used for advanced engine testing. At full load the emissions of NOx values are 890 PPM (diesel), 945 PPM (2EE blend), 955 PPM (DGM blend), and 897 PPM (2ME blend) respectively.

Figure 8: Comparison of Nitrogen oxides

Smoke Emissions

The smoke in the engine exhaust is the net result of soot formation and the subsequent oxidation during the combustion process. Fig.9 shows the comparison of smoke intensity with respect to brake power for diesel and oxygenated blends. The experimental result shows that all the three oxygenated fuels reduce the smoke level. It is evident that DGM blend reduces the smoke considerably compared to diesel and other two blends with diesel. The enrichment of oxygen content in the fuel due to addition of oxygenated fuel result in better combustion and therefore the smoke content in the exhaust is reduced.

Figure 9: Comparison of smoke intensity

Engine Specifications

Type of Engine : single cylinder Diesel engine

Bore/Stroke : 102mm/118mm

Compression ratio : 17.5:1

Rated speed : 1500rpm

Injection pressure : 200 bar

Injection timing : 26°C BTDC

Maximum power : 10 hp

Conclusion

The combustion, performance and emission characteristics of a DI compression ignition engine fuelled with oxygenated blends with diesel have been analysed and compared to diesel fuel. The following conclusions were drawn.

2ME blend increases the peak pressure and heat release rates compared to diesel fuel. Addition of DGM and 2EE blends with diesel decreases the peak pressure and heat release rates.

Brake thermal efficiency of blended fuels is increased with increase in Brake power. Addition of 2EE, 2ME and DGM blends with diesel reduces fuel consumption.

The CO emissions were reduced with the addition of 2EE, DGM and 2ME blends which is strong advantage of using oxygenated fuels. Blends of DGM and 2EE decreases the HC emissions compared to diesel fuel. 2ME blend increases the HC emissions compared to diesel fuel.

NOx emission increases with the addition of DGM and 2EE blends with diesel fuel. Marginal increase in NOx was observed with 2ME blend.

It is observed that addition of oxygenated compounds reduces the smoke intensity at all loads.

Based on this research work it is concluded that 6% 2ME blend with diesel fuel is found to be effective in improving the diesel engine combustion, performance and emissions compared to other two oxygenated fuels and diesel fuel.

References

- Bailey B. Eberhardt J. Goguen S. and Erwin J., “Diethyl Ether (DEE) as a renewable diesel fuel,” SAE Paper No. 972978.

- Ofner H. Krotschec C. and Gill D.W.,“Dimethyl ether as fuel for CI Engines-A New Technology and its Environmental Potential”SAE Paper No. 981158.

- Natarajan M. et al., “Oxygenates for Advanced Petroleum – Based Diesel Fuels: Part 1. Screening and Selection Methodology for the Oxygenates,” SAE 2001-01-3631.

- Zannis T.C. Hountalas D.T. and Kouremenos D.A., “Experimental Investigation to Specify the effect of Oxygenated Additive Content and type on DI Diesel Engine Performance and Emissions,” SAE 2004-01-0097.

- Ruijun Z. et al., “Performance and Emission Characteristics of Diesel engines fuelled with Diesel-Dimethoxymethane (DMM) blends,” Energy & Fuels, 23: 286-293 (2009).

CrossRef

- Huang Z.H. Jiang D.M. Zeng K. and Yang Z.L., “Combustion characteristics and heat release analysis of a DI compression ignition engine fuelled with Diesel-Dimethyl Carbonate blends,” Proc. IMechE. Part D: J.Automobile Engineering. 217: 595-605 (2003).

CrossRef

- Miyamoto N. Ogawa H. Md.Nurun N. Obata K. and Arima T., “Smokeless, Low NOx, High thermal efficiency and Low Noise Diesel Combustion with oxygenated Agents as Main fuel,” SAE paper No. 980506.

- Litzinger T. Stoner M. Hess H.S. and Boehman A.L., “Effects of Oxygenated blending compounds on emissions from a Turbo-charged Direct injection Diesel engine,”International Journal of Engine Research, 1:57-70 (2000).

CrossRef

- Ying W. Longbao Z. Zhongji Y. and Hongyi D., “Study on the Performance and Emissions of a Compression Ignition Engine fuelled with Di-methyl Ether,” Proc. IMechE. Part D: J. Automobile Engineering . 219: 263-269 (2005).

CrossRef

- Sirman M.B. Owens E.C. and Whitney K.A., “Emissions Comparison of Alternative fuels in an Advanced Automotive Diesel Engine,”SAE 2000-01-2048

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal