R. Vijayaragavan1* and S. Mullainathan2

*1Department of Physics, Arasu Engineering College, Kumbakonam, Tamilnadu, India.

2Department of Physics, A.V.C. College of Engineering, Mayiladuthurai, Tamilnadu, India.

DOI : http://dx.doi.org/10.13005/msri/080121

Article Publishing History

Article Received on : 02 Jan 2011

Article Accepted on : 12 Feb 2011

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

A lot of research is currently being done recycling, into how to reuse the waste we produce in our daily lives. This paper presents some of the results from a continuous study of recycling municipal solid waste ash (MSW-ash) into brick materials. In present study, the mixture of municipal solid waste ash and clay are used to make standard bricks fired at 900?C & 950?C. Physical characteristics including density, firing shrinkage, compressive strength and water absorption test of brick materials are reported and discussed. The results of test indicated that the municipal solid waste ash proportion and firing temperature were the two key factors determining the quality of bricks.

KEYWORDS:

Properties; Bricks; Municipal solid waste ash; Firing temperature; Recycling

Copy the following to cite this article:

Vijayaragavan R, Mullainathan S. Production of Brick Materials from Municipal Solid Waste Ash. Mat.Sci.Res.India;8(1)

|

Introduction

Accumulation of waste can be considered as one of the main sources for the environmental pollution. In the last few years, many researchers were interested in studying the problem of industrial wastes. Landfilling of municipal solid waste are not universally, environmentally sustainable and economically feasible disposal methods. Incineration of municipal solid waste is also a seemingly unsustainable solution as emissions from the burning waste (ash) contain various hazardous substances.1 Recycling of municipal solid waste ash by incorporating them into building or ceramic materials is a practical solution to the pollution problem.

This paper describes some of the procedures and results from a study on incorporating municipal solid waste ash (MSW-ash) into brick specimens. Properties (density, linear shrinkage, compressive strength and water absorption test) of brick specimens with different MSW-ash additions are presented and discussed.

Experimental

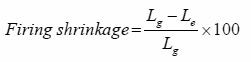

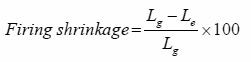

The materials used in this research work are municipal solid waste ash (MSW-ash) and clay. The MSW-ash and clay mixtures were then intruded into a series of standard bricks molds (8.0 X 4.5 X 2.5 cm). After forming, the specimens were dried in open atmosphere (3 days) and then in an oven dried for 24 hours at 110 °C. Then dried samples were fired at 900 and 950 °C respectively for 1 hour in a muffle furnace. The physical parameters of fired brick specimens, viz, density, firing shrinkage, compressive strength, and water absorption determined. The bulk density was evaluated by dividing accurately measured mass of sintered samples by external volume (dimensional method 2). The firing shrinkage (%) was evaluated using the formula

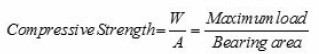

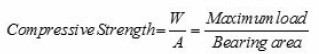

Where by Lg and Ls are the accurate by measured length of green and sintered samples, respectively 3. The Compressive strength was tested using Compressive testing machine. The rate of pressure applied to brick break and break point was measured for compressive strength. The Compressive strength was calculated using the formula.4

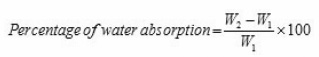

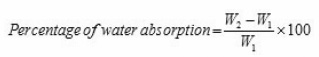

The Water absorption (%) of the sintered brick was determined using the procedure outlined in the Indian Standards Specifications.5 The Water absorption (%) was calculated using the formula.2&6

Where by W1 and W2 are the weight of the fired specimen and weight of the brick specimen after 24 hours of immersion in water.

Results and Discussion

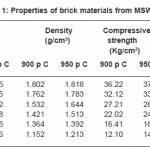

At least five samples were used in each test for all categories and the average values are presented and discussed in this section. In the present study, the brick materials are analyzed Density, Firing shrinkage , Compressive strength and Water absorption test and this reports are summarized in table 1.

Table 1: Properties of brick materials from MSW-ash

Density of Bricks

The brick specimens made with clay normally have a bulk density of approximately 2.00 g/cm3. The measurements of bulk density for different proportions of MSW-ash brick fired at two temperatures (900 and 950°C) are demonstrated in figure 1. As shown, the bulk density of brick specimens is inversely proportional to the quantity of MSW-ash added in the mixture. This finding is closely related to the quantity of water absorbed as demonstrated in figure 4. When brick absorb more water, it exhibits a large pore size, resulting in a light density.6 The firing temperature can also affect the bulk density of the bricks.6 The results show that increasing the temperature results in an increase in bulk density. In the present investigation, a linear relationship between the density and MSW-ash proportion in the mixture for two temperatures are observed.

Figure 1: Effect of MSW-ash addition on Density of the brick materials

Firing Shrinkage of Bricks

The quality of brick can be further assured according shrinkage to the degree of firing.6&7 Normally good quality brick exhibits shrinkage below 8%. For a brick, the shrinkage is 2.55 – 0.42 (%) and 2.85 – 0.50 (%) at firing temperatures of 900°C and 950 °C. The firing temperature is another parameter affecting the degree of shrinkage.6&7 High shrinkage causes destruction of bricks both in firing and drying stages of production. Shrinkage in bricks occurs as chemically and mechanically bound water is lost. A linear relationship between the shrinkage and the MSW-ash proportion was observed for 5 to 25 % MSW-ash added. In general, increasing the firing temperature results in an increase in shrinkage (fig.2).

Figure 2: Effect of MSW-ash addition on firing shrinkage of the bricks

Compressive Strength of Bricks

The compressing test is the most important test for assuring the engineering quality of building materials.7&8 The variation in Compressive strength of the brick specimen made from clay–MSW ash mixture is shown in figure 3. The results indicate that the strength is greatly dependent on amount of MSW-ash in the brick and the firing temperature. Fig. 3 shows that the compressive strength of bricks decreases with the increase of the MSW-ash mix in the bricks.

Figure 3: Effect of MSW-ash addition on Compressive strength of the bricks

Water Absorption Test of Bricks

Water absorption is a key factor affecting the durability of brick. The less water infiltrates into brick, the more durability of the brick and resistance to the natural environment are expected.7 Thus, the internal structure of the brick must be intensive enough to avoid the intrusion of water. The Water absorption was determined by using the standard procedure9 described in ASTM C67 (1998).

Fig. 4 shows the results of the test for different proportions of MSW-ash in the mixture fired at two temperatures. As shown, the water absorption for the bricks increases with increased MSW-ash addition and decreased firing temperature, thereby decreasing its weathering resistance.6 According to the criterion of Water absorption of bricks in ASTM C67 (1998), the ratio is below 17% for first class brick and 17 to 22% for second class brick. When the mixture contains less than 10% MSW-ash and is fired at 900°C and 950 °C, the brick products, should belong to the first-class category based on the percentage of absorbed water.

Figure 4: Effect of MSW-ash addition on Water absorption of the bricks

Conclusions

This research work has demonstrated a feasible way of using incinerated municipal solid waste ash (MSW-ash) as clay substitute to produce quality bricks. Different measurements of both clay -ash admixtures and brick were carried out to evaluate the factors that could affect brick quality. Major findings in the study are as follows.

In order to yield a good quality brick, the proportion of MSW-ash in the mixture and firing temperature are important key factors controlling the shrinkage in the firing process. Increasing the firing temperature results in an increase in shrinkage.

The bulk density of brick samples is directly proportional to the firing temperature and the density of the brick samples gradually decreases with increasing MSW-ash addition.

The results of compressive strength tests on the bricks made from both clay and municipal solid waste – ash indicate that the strength is greatly dependent on the amount of MSW-ash in the brick and the firing temperature.

The amount of water absorption is inversely proportional to firing temperature and the amount of water absorption is also directly proportional to quantity of MSW-ash added.

It is concluded from the present studies, the optimum amount of municipal solid waste -ash could be mixed with clay to produce good bonding of brick was 5% by weight and fired at 950 °C gives the most favourable results.

References

- Knox, A., “An overview of incineration and EFW technology as applied to the management of Municipal solid waste (MSW)”, ONEIA Energy subcommittee,(2005).

- Monteriro, S.N., Pecanha, L.A. and Vieira,C.M.F., Journal of the European Ceramic Soc., 24(8): 2349-2356 (2004).

CrossRef

- Navin Chandra, Nitin Agnihotri, Sanjeev Bhasin, and Khan, A.F., Journal of the European Ceramic Soc. 25: 81-88 (2005).

- Vijayaragavan, R., Janikiraman, G.,Satheeskumar, M., Balachandramohan, M.,Viruthagiri, B. and Rajamannan. B., Acta Ciencia Indica, 34: 023-027 (2008).

- Indian Standards Specification No 777 (1990).

- Deng-Fong Lin and Chih-Huang Weng,Journal of Environmental Engineering,127(10): 922-927 (2001).

CrossRef

- Rouf, M.A. and Hossain, J.N.F., “Effect of using arsenic –iron sludge in brick making”www.freeonline journal.com (2004).

- Vijayaragavan, R., Balachandramohan, M.,Praveen Kumar, S. and Prasana, T., Acta Ciencia Indica, 33: 043-048 (2007).

- ASTM C67, “Standard test method for sampling and testing brick and Structural clay Tiles”, ASTM International, West Conshohocken, PA. (1998).

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal