M. K. Lalji1*, R. M. Sarviya2 and J. L. Bhagoria1

1Department of Mechanical Engineering, MANIT, Bhopal- 462 052, India.

2Department of Technical Education and Skill Development, M.P. Govt, S.V. Polytechnic College, Shyamla Hills, Bhopal - 462 002, India.

DOI : http://dx.doi.org/10.13005/msri/080114

Article Publishing History

Article Received on : 20 Apr 2011

Article Accepted on : 30 May 2011

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

Solar energy is an economical alternative to the today's energy demand. Solar air heater is used for heating the air economically but produces low thermal efficiency. In this paper, an attempt has been made to study the design of solar heaters to increase the thermal efficiency. The matrix solar air heater with a wire mesh produces higher thermal efficiency over the conventional flat plate solar air heater. The evaluation of different methods for increasing efficiency of packed bed solar air heater has been done . Effect of different parameters on thermal efficiency of solar heater has also been studied.

KEYWORDS:

Solar energy; Solar-heater; Thermal-performance; Wire-mesh

Copy the following to cite this article:

Lalji M. K, Sarviya R. M, Bhagoria J. L. Various Designs of Solar Collectors for Enhancement of Thermal Performance. Mat.Sci.Res.India;8(1)

|

Copy the following to cite this URL:

Lalji M. K, Sarviya R. M, Bhagoria J. L. Various Designs of Solar Collectors for Enhancement of Thermal Performance. Mat.Sci.Res.India;8(1). Available from: http://www.materialsciencejournal.org/?p=2504

|

Introduction

Solar air heaters have a low efficiency due to low convective heat transfer coefficient between the air and absorber plate, which leads to higher temperature of the absorber plate resulting in maximum thermal losses to environment (Prasad & Mullick1). If the area available for heat transfer is not greater than the projected area of the absorber, the absorber becomes necessarily hot, which leads to higher heat losses. Researchers have attempted various modifications in solar air heater to enhance the heat transfer rate by incorporating modifications between absorber plate and glass plate such as using an absorber with fins attached, corrugated absorber (Choudhury et al.,2), porous materials such as stones (Swartman & Ogunladeo,3), crushed glass, wool and metal wool.

Flat Plate Collectors

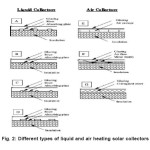

Unlike the concentrating collectors, the flat plate collectors use both the beam and diffuse radiations If the area of interception of solar radiation is same as the area of absorption, the collector is known as flat plate collector. Flat plate collectors are designed for applications requiring energy delivery at low to moderate temperatures. These units are mechanically simpler than the concentrating collectors. A flat plate collector is installed facing the sun (at an optimum inclination to the horizontal depending on the latitude of a location) and hence does not require tracking of the sun. The major applications of the flat plate collectors are in solar water heating and air heating areas. Flat plate collectors may be divided into two main classifications based on the type of heat transfer fluid: (a) Liquid heating collectors & (b) Air heating collectors or Solar air heaters

Various Designs of Solar Collectors for Enhancement of Thermal Performance

Solar air heaters having higher thermal losses to the environment and hence lower thermal efficiency. It is therefore, necessary to improve convective heat transfer coefficient to increase the thermal efficiency of flat plate solar air heaters. To enhance the thermal efficiency research attempts have been made by modifying the conventional design of solar air heater. Several different designs have been proposed to increase the heat transfer coefficient between the absorber plate and the air. To reduce the heat losses to the atmosphere, the effect of use of more than one glass covers, vacuum or other media between glass cover and the absorber plate, honeycomb, multipass air flow, overlapped glass plates as absorber and absorber with selective surface have been investigated. All of these are described as follows:.

Simple Flat Plate Collector

This is the simplest and most commonly used type of collector. In its simplest form, it is composed of one or two glazing over a flat plate backed by insulation. The path of air flow may be either above or below or both above and below the absorber plate.

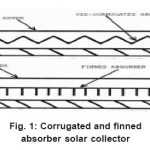

Finned Plate Collector

This is a modified version of flat plate collector where the heat transfer coefficient is increased by using fins on the flat plate absorber and in certain designs the surface is made directionally selective. The fins are usually located in the air flow passage.

Corrugated Absorber Type Collector

This is another version of the simple flat plate collector in which the absorber is corrugated either in rounded troughs. This increases the heat transfer area and may make the surface directionally selective.

Figure 1: Corrugated and finned absorber solar collector

Matrix Type Collector

In this design an absorbing matrix is placed in the air flow passage between the glazing and absorbing plate. The matrix material may be expanded metal plate, cotton gauge or loosely packed porous material. This type of collector offers a high heat transfer to volume ratio. Also it offers low friction losses depending on the design.

Overlapped Transparent Plate Type Collector

This type of collector is composed of a staggered array of transparent plates which are partially blackened. The air flow passage is between the overlapped plates

Porous Collector

The porous or transpiration bed design is a variation of matrix type collector in which the matrix material is closely packed and the back absorber plate is eliminated. The air flow usually enters just under the innermost cover and flows downward through the porous bed and into the distribution ducting.

Two or More Glass Covers Type Collector

When collector operates at high temperatures or is subjected to high wind velocity, use of two or more glass covers placed at a certain height above the absorber plate reduces the convective as well as radiative heat losses from the collector. But the use of several glass covers reduces the amount of insolation reaching the absorber plate due to absorption of the solar radiation by the glass.

Alternative Media or Vacuum in the Gap Space

By filling the gap between the glass cover and the absorber plate with alternate media shows reduction in losses. The use of heavy glasses such as argon can result in a 34% reduction in convective heat losses. This saving is more than 50% for two cover system.

Honeycomb Convection Suppression

Convection from the absorber plate to the glass cover can be suppressed by filling the space between the absorber plate and glass cover called honeycombs Holland. Due to the suppression of the motion of the air, the heat transfer between the plate is mainly be conduction and radiation.

Two Pass Air Flow Type Collector

A two-pass solar air heater consist of two glass covers, an absorber plate, and a rear plate. The air is first made to pass through the channel formed by two glass covers and then through the channel formed by the rear plate and the absorber plate.

This type of collector is not suitable when the incoming air is at temperature well above the atmospheric temperature because air flowing on the top side of absorber plate may cause substantial loss from the inlet air to ambient by way of convective heat transfer to the inner glass cover and subsequently out to ambient. The dust in the air, if any, will build up on the inside surface of the temperature cover thus reducing the transmittance of the cover.

Absorber Plate with Selective Surfaces

It is desirable to obtain absorber plate surface with the combination of high absorbance for solar radiations and low emittance for long wave radiations. It is possible to achieve this combination of properties because there is very little overlap in wavelength ranges of the solar radiations and long wave radiations. Coatings having high absorption for solar radiations and low emittance for long wave radiations can be applied to substrates. The properties of surface coatings used in the flat plate collectors. These are “nickel black” on galvanized iron, “copper black” on copper, ebanol copper on copper and “black chrome” plating on nickel plated steel. The experimental coatings reported are copper oxide on anodized aluminium or nickel, interference layers of aluminium-molybdenum compounds on molybdenum and lead sulphide crystals on aluminium. Absorber plate with highly selective surfaces requires only one transparent cover even at fairly high operating temperatures.

Tank Type Collector

In an Integral storage collector unit, the hot water storage tank is the solar absorber. The tank or tanks are mounted on the insulation box with glazing on one side and are painted with black or coated with a selective surface. The sun shines through the glazing and hits the black tank, warming the water inside the tank. The single tanks are typically made of steel, while the tubes are typically made of copper. Achievable temperature with such collectors is a little bit less then in flat-plate collectors.

Pool Collector

The single largest application of active solar heating systems is in heating swimming pools. Special collectors have been developed for heating seasonal swimming pools: they are unglazed and made of special copolymer plastic. These collectors cannot 25 With-stand freezing conditions. Approximate maximum operating temperature of such type of solar collector is 10-20 °C above ambience.

Figure 2: Different types of liquid and air heating solar collectors

Evacuated Tube Collectors

Evacuated tube collectors are mostly used to heat water in residential applications that require higher temperatures. Sunlight enters through the outer glass tube and strikes the absorber tube(s) and changes to heat. The heat is transferred to the liquid flowing through the absorber tube. The collector consists of rows of parallel transparent glass. The tubes are designed in such a way that air is evacuated from the space between the two tubes forming a vacuum. Conductive and convective heat losses are eliminated because there is no air to conduct heat nor to circulate and cause convective losses.

Performance of solar collectors

The investigation performance of double pass-finned plate solar air heater has been done by The results of A.A. El-Sebaii et al.4 showed that the double pass v-corrugated plate solar air heater is 9.3–11.9% more efficient compared to the double pass-finned plate solar air heater. It was also indicated that the peak values of the thermo hydraulic efficiencies of the double pass-finned and v-corrugated plate solar air heaters were obtained when the mass flow rates of the flowing air equal 0.0125 and 0.0225 kg/s, respectively.

Evaluation of thermal performance of wire mesh solar air heater by P. Velmurugan et al.,5 employing a low carbon steel wire mesh observed 5% increase in overall efficiency is observed when compared with conventional system. Mass flow rate influences the thermal efficiency of the air heater. Solar intensity has no effect on thermal efficiency.

Optimization of bed parameters for packed bed solar energy collection system has been carried out by B. Paul et al.,.6 In this work two types of packed bed collectors, one with wire mesh screen matrix bed and other with pebble bed, were optimized on the basis of minimum cost per unit energy delivered.

Five different shapes of elements of storage material have been investigated by Ranjit Singh et al.,.7 Effect of system and operating parameters on heat transfer and pressure drop characteristics of packed bed solar energy storage system with large sized elements of storage material has been done Correlations have been developed for Nusselt number and friction factor as function of Reynolds number, spheriocity and void fraction

Thermo hydraulic investigations on a packed bed solar air heater having its duct packed with blackened wire screen matrices of different geometrical parameters (wire diameter and pitch) has been done by M.K. Mittal et al.8 Based on energy transfer mechanism in the bed, a mathematical model is developed to compute effective efficiency. A design criterion is also suggested to select a matrix for packing the air flow duct of a solar air heater which results in the best thermal efficiency with minimum pumping power penalty.

In an experimental investigation carried out by L. Varshney et al.,9 on heat transfer and fluid flow characteristics of a solar air heater having its duct packed with wire mesh screen matrices. The investigations covered a wide range of geometrical parameters of wire mesh screen matrix (wire diameter, pitch and number of layers). Correlations developed for Colburn j-factor and friction factor indicate that heat transfer coefficient and friction factor are strong functions of geometrical parameters of matrices.

N.S. Thakur et al.,10 done experimental investigation on a low porosity packed bed solar air heater covering a wide range of geometrical parameters of wire screen matrix, i.e. wire diameter 0.795 to 1.40 mm, pitch 2.50 to 3.19 mm and number of layers from 5 to 12. It is observed that both the heat transfer coefficient and the friction factor are strong functions of geometrical parameters of the porous packed bed. A decrease in porosity increases the volumetric heat transfer coefficient.

M.K. Gupta et al.,11 carried out comparative study of various types of artificial roughness geometries in the absorber plate of solar air heater duct and their characteristics, investigated for the heat transfer and friction characteristics.. It is found that artificial roughness on absorber surface effectively increases the efficiencies in comparison to smooth surface.

Conclusions

The packed bed type solar air heater can be successfully used to enhance the heat transfer rate. The high heat transfer area to volume ratio promotes heat transfer capability and the turbulence producing airflow path through the bed provide for a rapid increase of heat exchange. Porosity strongly influences the heat transfer coefficient and hence thermal performance of packed bed solar air heater. It can also be concluded that a considerable enhancement of heat transfer can be obtained from the packed bed solar air heater by lowering the porosity of the bed. The porosity of the bed governs the performance of packed bed solar air heater at a given Reynolds number, the porosity and area to volume ratio are the key parameters for heat transfer. The Reynolds number also has been found to be a strong parameters affecting heat transfer and friction factor for packed bed solar heater.

References

- Prasad K., Mullick S.C., Heat transfer characteristics of a solar air heater used for drying purposes. Applied Energy, 13: 83-93: (1983).

CrossRef

- Choudhury C, Garg HP and Prakash J, Design studies of packed-bed solar air heaters, Energy Conversion Management. 34(2): 125-138. (1993).

CrossRef

- Swartman R. K.and Ogunade O., An investigation on packed bed collectors. Solar Energy, 10: 106-110 (1966).

CrossRef

- El-Sebaii A.A, Aboul-Enein S, Ramadan MRI, Shalaby SM and Moharram BM, Thermal performance investigation of double pass-finned plate solar air heater. Applied Energy. 88, 1727–1739. (2011).

CrossRef

- Velmurugan P. and Ramesh P., Evaluation of thermal performance of wire mesh solar air heater, Indian Institute of Science & Technology., 4(1): 12-14: (2011)

- Paul B and Saini JS, Optimization of bed parameters for packed bed solar energy collection system. Renewable Energy. 29: 1863-1876. (2004).

CrossRef

- Singh R, Saini RP and Saini JS, Nusselt number and friction factor correlations for packed bed solar energy storage system having large sized elements of different shapes. Solar Energy. 80: 760-771 (2006).

CrossRef

- Mittal MK and Varshney L, Optimal thermo-hydraulic performance of a wire mesh packed solar air heater. Solar Energy. 80: 1112–1120 (2006).

CrossRef

- Varshney L and Saini JS, Heat transfer and friction factor correlations for rectangular solar air heater duct packed with wire screen matrices. Solar Energy. 62(4): 255-262 (1998).

CrossRef

- Thakur NS, Saini JS and Solanki SC, Heat transfer and friction factor correlations for packed bed solar air heater for a low porosity system. Solar Energy. 74: 319-329 (2003).

CrossRef

- Gupta M.K. and Kaushik S.C., Performance evaluation of solar air heater having expanded metal mesh as artificial roughness on absorber plate, 48: 1007-1016 (2009).

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal