Nephelene syenite is a holocrystalline plutonic rock that consists largely of Nepheline and alkali feldspar. Other minerals common in minor amounts include sodium-rich pyroxene, biotite, titanite, zircon, iron oxides, apatite, fluorite and zircon.The rocks are mostly pale colored, grey, pink or greenish black, and in general appearance they are not unlike granites, but dark green varieties are also known. Nepheline syenites are silica-undersaturated. Nepheline is a feldspathoid, a solid-solution mineral, that does not coexist with quartz; rather, Nepheline would react with quartz to produce alkali feldspar.They are distinguished from ordinary syenites not only by the presence of Nepheline but also by the occurrence of many other minerals rich in alkalis and in rare earths and other incompatible elements. Alkali feldspar dominates, commonly represented by orthoclase In some rocks the potash feldspar, in others the soda feldspar predominates. Fresh clear microcline is very characteristic of some types of Nepheline syenite.

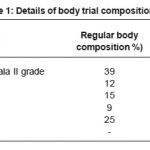

Nepheline-syenites are rich in alkalis and in alumina (hence the abundance of felspathoids and alkali feldspars) with silica varying from 50 to 56%, while lime and magnesia are never present in great quantity, though somewhat more variable than the other components. A worldwide average chemical analysis of Nepheline syenite is given in the Table 2 (G.W.Tyrrell,1926) Average chemical analysis of Nephline syenite indicates that it is having fluxes to the extent of 13.8 % and in addition to that it is having 5.7 % iron oxides which also acts as flux.

Table 2: Average chemical analysis of Nepheline syenite

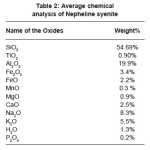

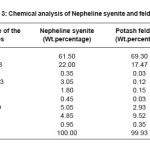

Observation of fired cone indicates that the material under study has more maturity indicating more fluxing nature and also marginally lower maturing temperature than potash feldspar.and fired colour is deep red brown. Chemical analysis of nephelene syenite indicates (Table –3) it is having fluxes (Na2O + K2O) to the extent of 9.9 % and in addition to that it is having 3.05 % iron oxides which also acts as flux. Potash feldspar is having fluxes to the extent of 12.5 %. Total amount of fluxes in Nepheline syenite is 13.4 % which is 0.9 % higher than potash feldspar indicating high flux nature. No significant variation in residue levels is observed in grinding and also no significant variation in viscosity is observed.

Table 3: Chemical analysis of Nepheline syenite and feldspar

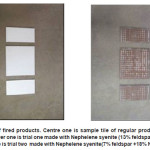

Marginal increase is observed in fired strength, fired shrinkage, decrease in water absorption in trial made with Nepheline syenite. Further slight positive warpage is observed in trial two and body colour of trial two is slightly darker than other two. Samples of trials made with Nepheline syenite also passes in crazing resistance, surface abrasion resistance, thermal shock resistance and chemical resistance and they are comparable with the results of regular body.

More maturity and flowability of fired cone, relatively higher percentage of Na2O, K2O and Fe2O3 indicate that Nepheline syenite under study is having more flux nature than Potash feldspar. Marginal increase observed in fired strength, shrinkage, decrease in water absorption in trial one and two indicates that Nepheline syenite under study confirms that it is having more flux nature than Potash feldspar. Results of trial 1 and trial 2 are almost comparable with results of body in product performance. Potash feldspar can be replaced with Nepheline syenite of understudy to the extent of 50 percent in red body glazed ceramic tiles.

The cost of nephlene syenite is cheaper than potash feldspar by Rs 400/ MT. By replacing Nepheline syenite in feldspar to the extent of 50%,the cost of body raw materials of glazed tile can be brought down to the extent of 10 % and final product cost can be brought down .However these results are based on lab scale only and these results are to be conformed by making a trial in production scale.

In a tile plant of 40,000 sq.mts capacity per day when feldspar is replaced with 50 % Nepheline syenite, cost of raw materials will come down by Rs 7.50/ sq.mt. Cost reduction only on raw materials comes to Rs.3.0 lakh per day. Assuming that plant operates for 330 days at 90 % capacity utilization, total cost savings in the plant by replacing feldspar with 50 % Nepheline syenite comes to Rs 8.9 crores per anum.

The huge amount of feldspar deposits is using in the ceramic industry due to this the resources are getting depleted, keeping this in view the alternative resources is required for industry. In this connection replacement of feldspar with Nepheline syenite is very much useful for sustainability of the ceramic industry and these nephline synite deposits are occurring in huge quantity in Elchuru, Prakasham District (Leelanandam, 1989); Kunavaram, Khammam District, ( Bose, etal. (1971) of Andhra Pradesh, Kishangarh, Ajmer District, Rajasthan, Mount Girnar, Gujarat, Western India, Sivanmalai, Coimbatore District, Tamil Nadu (B. Bhaskar Rao), Koraput, Orissa of India.

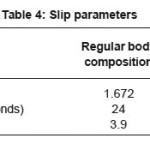

Table 4: Slip parameters

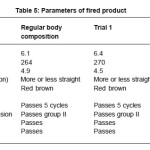

Table 5: Parameters of fired product

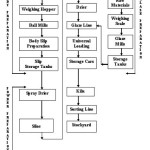

Figure 1: Step by step Processing of methodology

Figure 2: Showing samples of Nepheline synite and potash feldspar

Figure 3: Samples of fired products. Centre one is sample tile of regular production made with feldspar (25%). lower one is trial one made with Nephelene syenite (13% feldspar +12% Nephelene syenite), Upper one is trial two made with Nephelene syenite(7% feldspar +18% Nephelene syenite)

Figure 4: Showing testing of sample for surface abrasion resistance

Acknowledgements

The authors express sincere thanks to the management of M/s Spartek Ceramics India Limited for permitting to publish the paper.

References

- Leelanandam, C., The Prakasam alkaline province in Andhra Pradesh. Jour. Geol. Soc. India, 53: 41-52 (1989).

- Bose, Mihir K. ; Chakravarti, S. ; Sarkar, A.,Petrological observations on alkali syenitesof Kunavaram, A. P., India Geological Magazine, 108: 273-280 (1971). ISSN 0016-7568

- B. Bhaskar Rao Petrology of the alkaline rocks around Sivamalai, Coimbatore District,Tamil Nadu, India International Journal of earth sciences 71(1): 263-279.

- Bose, Mihir K., Petrology of the Nepheline syenite of Mount Girnar, India Lithos, 4(4):pp. 357-366 (1971). ISSN 0024-4937

- Bureau of Indian standards, IS -15622 pressed ceramic tiles Specifications (2006).

- The principles of petrology ,page.117, G.W.Tyrrell,, Asia Publishing House (1926).

- Czygan W., Goldenberg G. Petrography and geochemistry of the Alkaline complexes of Sivanmalai, Elchuru and Upallapadu, India. Geol.Soc.India Memoir 15: 225-240.

- Hamilton, D. L. and MacKenzie, W. S., Phase equilibrium studies in the system NaAlSiO4(Nepheline)-KAlSiO4(kalsilite)- SiO4(quartz)-H2O. Min. Mag., 34: 214-231 (1965).

- Krishna Reddy, K. K., Ratnakar, J. and Leelanandam, C., A petrochemical study of the Proterozoic alkaline complexof Uppalapdu, Prakasam alkaline province,Andhra Pradesh. Jour. Geol. Soc. India, 53:41-52 (1998).

- Leelanandam, C., The Prakasam alkaline province in Andhra Pradesh. Jour. Geol. Soc.India, 53: 41-52 (1989).

- Leelanandam, C., Burke, K., Ashwal, L. D. and Webb, S. J., Proterozoic mountain building in Peninsular India: an analysis based primarily on alkaline rock distribution.Geol. Mag., 143: 195-212 (2006).

CrossRef

- Madhavan V., Mallikhavrjuna R., Subrahmanyam K., Krishna S.G.,Leelanandam, C., Bedrock geology ofElchuru Alkaline Pluton, Prakasam Disreict,Andhra Pradesh. Geol.Soc.India Memoir 15: 189-205 (1989).

- Ratnakar, J., Vijaya Kumar, K. and Rathna,K.. Meso-Proterozoic rifting and Grenville /Pan-African collision in the Prakasam alkaline province, Andhra Pradesh, southern India: Evidence from Nepheline syenitecompexes. International Conference on Tectonics of the Indian Subcontinent (TOIS),Intern. Assoc. Gond. Res. Conf. Ser., 5: 194-196 (2008b).

- Subba Rao T.V., Bhaskar Rao Y.J. Sivaraman T.V., Gopalan K. Rb-Sr age and petrology of the Elchuru alkaline complex: Implication to the alkaline magmatism in the Eastern Ghat mobile belt.// Memeirs Geol. Sci. of India, 15:pp. 207-223 (1989).

- Ratnakar, J., Precambrian alkaline complexes of southern India. International Seminar on Alkaline Igneous Systems:Dissecting Magmatic to Hydrothermal Mineralizing Processes. Canada, Abstracts,p. 126 (2006).

- Ratnakar, J. and Leelanandam, C., A petrochemical study of the Purimetla alkalinepluton, Prakasam District, Andhra Pradesh, India. Neues Jahrbuch Mineral.Abh., 156:99-119 (1986).

- Upadhyay, D., Raith, M. M., Mezger, K. and Hammerschimdt, K., Mesoproterozoic riftrelated alkaline magmatism at Elchuru, Prakasam alkaline province, SE India. Lithos,86: 447-477 (2006).

CrossRef

- Vijaya Kumar, K., Frost, C. D. Frost., R. B. Frost.and Chamberlin, R., The Chimakurthi, Errakonda and Uppalapadu plutons,Eastern Ghats belt, India: an unusual association of tholeiitic and alkaline magmatism. Lithos, 97: 30-57 (2007).

CrossRef

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal