Software for Computing Properties of Composite Materials from Sawdust/Palm Kernel Shell

J. O. Osarenmwinda* and J.C Nwachukwu

Department of Production Engineering, University of Benin, Benin City, Nigeria.

DOI : http://dx.doi.org/10.13005/msri/080208

Article Publishing History

Article Received on : 29 Jul 2011

Article Accepted on : 07 Sep 2011

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

Software was developed using visual basics for computing properties of developed composite materials from agro waste (sawdust and palm kernel shell). Visual Basic was used as a rapid application tool to compute the properties from previous experimental data and developed empirical models. The properties of the produced composite materials from agro waste estimated using the soft ware were hardness, yield strength, ultimate tensile strength, modulus of elasticity; modulus of rupture, internal bond strength, density, thickness swelling and water absorption .The values obtained from the software were found to compare favourably with the analytical values. The mean percentage error were determined to be 0.01% (hardness), 0.287% ( yield strength),0.003% (ultimate tensile strength), 0.00158% (modulus of elasticity), 0.2857% (modulus of rupture), 0% (internal bond strength), 00073%(density), 0.019% (thickness swelling) and 0.00768% (water absorption). These values were insignificant and below the maximum recommended error of 10%. The software performance was also found to be satisfactory, showed good predictability and user friendly.

KEYWORDS:

Agro waste; Composite material; Empirical model; Software; Visual basics

Copy the following to cite this article:

Osarenmwinda J.O and Nwachukwu J.C . Software for Computing Properties of Composite Materials from Sawdust/Palm Kernel Shell. Mat.Sci.Res.India;8(2)

|

Copy the following to cite this URL:

Osarenmwinda J.O and Nwachukwu J.C . Software for Computing Properties of Composite Materials from Sawdust/Palm Kernel Shell. Mat.Sci.Res.India;8(2). Available from: http://www.materialsciencejournal.org/?p=4110

|

Introduction

Materials research and development (R&D) has shifted from monolithic to composite materials, adjusting to the global need for reduced weight, low cost, quality, and high performance in structural materials.1 The demand for new materials with higher specifications led to the concept of combining different materials in an integral-composite one. Such composite materials result in performance that cannot be attained by the individual constituents. An additional advantage is that composite offer flexibility in design.2

Some of researchers have developed models and software for estimating properties of composite. Chunping et al.,3 carried out a study aimed to model fundamental bonding characteristics and performance of wood composite. In their work, a mathematical model and a computer simulation model were developed to predict the variation of inter-element (strand) contact during mat consolidation. The mathematical predictions and the computer simulations agree well with each other. Their results showed that the relationship between the inter-element contact and the mat density was highly nonlinear and was significantly affected by the wood density and the element thickness. Carldon and Matunana4 constructed a response surface model using a Box-Behnken design to statistically model and optimize the material compositions ( processing conditions) mechanical property relationships of formaldehyde-free wood composite panels. Three levels of binding agent content, pressing time, and press temperature were studied and regression models were developed to describe and optimize the statistically effects of the formulation and processing conditions on the mechanical properties of the panels. They observed that linear models best fit both the modulus of rupture (MOR)) and internal bond (IB) strength of the panels while flexural stiffness and modulus of elasticity (MOE) was best described by a quadratic regression model.

Visual basic is one of a range of programming languages that have been developed for the environment of Microsoft windows. It was written by the Microsoft corporation in about 1993 to allow programmers to code programs for windows. Visual Basic is an object–oriented language, developed from basic, which was also written by Microsoft. Visual Basic has the advantages of Basic, in that it is easy to use, and has a fairly comprehensive command set, but also allowing the programmers to write programs for Microsoft windows quickly and efficiently. The user writes the program using a number of frames, into which the code is inputted, the frames are then linked together to form the whole program. One of the biggest advantages of this sort of programming technique is that it allows the programmer to construct a user interface that can interact with the windows interface quickly, and because it is object oriented the programmer can assign bits of code to be activated if a certain action occurs.5

Repeatedly altering a commercial composite board manufacturing process to produce a predetermined properties was observed to be undesirable from economic and production standpoints.6,7 There also seems to be lack of an software to estimate the properties of composite materials from agro waste in particular composite from sawdust and palm kernel shell combination. This study therefore focuses on the development of computer software using visual basics 6.0 for estimating properties of produced composite material from agro waste (sawdust and palm kernel shell) making use of previously obtained experimental data and empirical model.8,9 This software it is hoped will help make the production and properties estimation of composite material from agro waste (sawdust and palm kernel shell) easier ,more accurate and faster, making of immense benefit to researchers, industrialist and small-scale manufacturers involved in composite material production.

Material and Methods

Materials

Sawdust from mahogany and palm kernel shell used to produced the composite material were obtained from Benin City, Edo State, Nigeria, while urea formaldehyde was used as binder.8

Composite Material Production

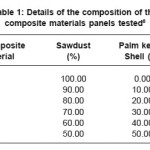

Osarenmwinda and Nwachukwu,8 have previously discussed the production of the Composite material from agrowaste (sawdust and palm kernel) using Table 1.They were produced with a particle size of 300µm and Urea formaldehyde binder concentration of 20% of the oven dry weight of agro waste.7

The Composite materials were evaluated for the following properties: thickness swelling ( 24hr immersion), water absorption ( 24hr immersion), modulus of rupture , modulus of elasticity , hardness, density, yield strength and ultimate tensile strength and Internal bond according to European Norm (EN) specifications.10-12

Table 1: Details of the Composition of the Composite Materials Panels Tested8

Model Formulation

In this work all empirical model was developed using the values obtained from previous experimental investigations for composite material properties.8 The empirical model was developed using “Mathmatical Product” software program expressing the outputs in the quadratic form as shown in Equation 1

Output = a0 + a1x+ a2x2 + a3 y+ a4 y2 …(1)

Where the input are as follows: x and y are sawdust composition and palm kernel shell composition in percentages respectively and a0, a1, a2, a3, a4 are constants.

The outputs are as follow: hardness (HRc),yield strength(N/mm2),ultimate tensile strength (N/mm2), modulus of elasticity (N/mm2), modulus of rupture(N/mm2), internal bond strength (N/mm2),density (Kg/m3), thickness swelling (%) and water absorption (%) respectively.

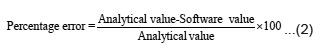

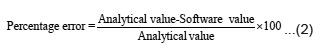

Percentage Error

The percentage error was determined using Equation (2)

The Assumptions Made in this Model and Software Development are as Follows:

The composite was of sawdust and palm kernel

The test binder was Urea formaldehyde applied at a concentrations of 20% (percentage of oven dry weight of agro waste) throughout the study.

Only agro waste (sawdust and palm kernel shell) particle size of 300µm was used .

All the composite production parameters were kept constant except composite agro waste constituent(sawdust and palm kernel)

Results and Discussion

Developed Empirical Model

The empirical models developed are as shown in Equations 3-119. They are as follow:

Hardness = –19.7016 – 0.344849x – 0.00511875x2 + 0.076577y- 0.00125447y2 …(3)

Yield strength = –1.01189 + 0.006555x – 0.0000584226x2 + 0.0680746y – 0.0043363y2 …(4)

Ultimate tensile strength = –1.56324 + 0.0114774x – 0.0000353483x2 + 0.0964542y + 0.000354991y2 …(5)

Modulus of elasticity = 741.366 + 6.99665x +0.015754×2 + 35.716y – 0.128611y2 …(6)

Modulus of rupture = –3.94653 + 0.0381715x + 0.000152525x2 + 0.184151y + 0.000395689y2 …(7)

Internal bond strength = 0.15064 + 0.0015024x + 0.00000594036x2 + 0.0067673y – 0.0000148689y2 …(8)

Density = 252.2 + 2.98596x + 0.0260344x2 +8.254722y + 0.0452549y2 …(9)

Thickness swelling = 3.68561 + 0.0741048x + 0.00127468x2 – 0.0762456y + 0.00122683y2 …(10)

Water absorption = 8.97721 + 0.149617x + 0.00204826x2 + 0.0136251y – 0.00122683y2 …(11)

The model was validated and found to be satisfactory and show good predictability of the model.9

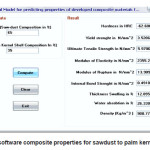

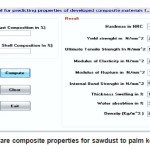

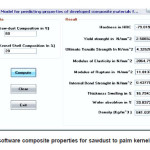

Visual basic application to computing predicted values software was developed using Visual Basics 6.0 for computing predicted composite materials properties. Visual Basic was used as a rapid application tool to compute the properties from empirical models. Figs. 1 – 4 show a samples of computed values, when the sawdust : palm kernel shell composition was 90% : 10%, 65%:35%, 73%:27% and 80 %:20% respectively. The values from this software program were found to be in conformity with the analytical values from developed model.

Figure 1: Computed software composite properties for sawdust to palm kernel shell ( 90% :10%)

Figure. 2: Computed software composite properties for sawdust to palm kernel shell ( 65% :35%)

Figure 3: Computed software composite properties for sawdust to palm kernel shell ( 73% : 27%)

Figure 4: Computed software composite properties for sawdust to palm kernel shell ( 80% : 20%)

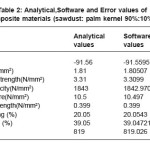

Accuracy of Software

The software accuracy was determined by comparing the model analytical values with the software values. The software values were found to compare favourably with analytical values (see Table 2 ) .The mean percentage error were determined to be 0.01% (hardness), 0.287%( yield strength),0.003 (ultimate tensile strength), 0.00158% (modulus of elasticity), 0.2857% (modulus of rupture), 0% (internal bond strength), 00073%(density), 0.019% (thickness swelling) and 0.00768% (water absorption). These values were insignificant and below the maximum recommended error of 10% proposed by Liping and Deku13. The software performance was also found to be satisfactory, showed good predictability and user friendly.

Table 2: Analytical,Software and Error values of composite materials (sawdust: palm kernel 90%:10% )

Conclusion

The software developed using visual basics for computing properties of composite material from agro waste(sawdust and palm kernel shell) have been achieved. The software was user friendly and its performance were found to be satisfactory and show good predictability. This software it is hoped will help make the production and properties estimation of composite material from agro waste (sawdust and palm kernel shell) easier ,more accurate and faster, making of immense benefit to researchers, industrialist and small-scale manufacturers involved in composite material production.

References

- J.U Ejiofor and R.G Reddy, Developments in the Processing and Properties of particulate Al-Si Composites. JOM 49(11): 31-37 (1997).

CrossRef

- F.A Gasser, A three-phase constitutive model for macrobrittle fatigue damage of composites. A PhD Dissertation Submitted to College of Engineering and Mineral Resources at West Virginia University, Department of Mechanical and Aerospace Engineering Morgantown, West Virginia.pp 1-5 (2000).

- D. Chunping, Y. Changing and Z. Cheng , Theoretical modeling of bonding characteristics and performance of wood composites: part 1.inter-element contact. Journal of wood and fiber science., 39(1): 48-55 (2007).

- K. Carlborn and L. M. Matuana, Modeling and optimization of formaldehyde-free wood composites using a Box-Behneken design. Polym. compos., 27: 497-503 (2006).

CrossRef

- V . Gupta, Comdex .Net programming course Kit. DreamTech Press, New Delhi, India (2010).

- T.E.G Harless, F. G. Wagner, P. H. Short, R. D. Seale, P. H. Mitchell, and D. S. Ladd., A model to predict the density profile of particleboard. Wood and Fiber Sci. 19(1):81-92 (1987).

- Osarenmwinda, J.O, Development of composite material from agro waste for industrial and domestic application. PhD Thesis , Department of Production of Engineering ,University of Benin, Benin city, Nigeria (2009).

- J.O Osarenmwinda and J.C Nwachukwu J.C, Development of Composite Material from Agricultural Waste. International Journal of Research in Africa 3: 42-48 (2010).

CrossRef

- J.O Osarenmwinda and J.C Nwachukwu, Empirical models for estimating properties of developed composite material from Agrowaste. Journal of Emerging Trends in Engineering and Applied Sciences 1(2): 178-182 (2010).

- EN 310. Wood based panels, Determination of modulus of elasticity in bending and bending strength. European standardization committee, Brussells (1993).

- EN 317. particleboards and fiberboards determination of swelling in thickness after immersion, European Standardization committee, Brussels (1993).

- EN 319. Particleboards and fiberboards determination of tensile strength perpendicular to plane of the board. European standardization committee, Brussels (1993).

- C. Liping, S. Deku, Modeling of the moisture transfer process in particleboards .Holz als Roh-und Werkstoff 50(10): 395-399 (1992).

CrossRef

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal