Response Surface Approach for Optimization of Sinker Electric Discharge Machine Process Parameters on AISI 4140 Alloy Steel

Manish Vishwakarma, V. K. Khare and Vishal Parashar

Department of Mechanical, M.A.N.I.T, Bhopal, India.

DOI : http://dx.doi.org/10.13005/msri/090113

Article Publishing History

Article Received on : 20 Mar 2012

Article Accepted on : 07 May 2012

Article Published :

Plagiarism Check: No

Article Metrics

ABSTRACT:

The purpose of this paper is to determine the optimal factors of the electro-discharge machining (EDM) process investigate feasibility of design of experiment techniques. The work pieces used were rectangular plates of AISI 4140 grade steel alloy. The study of optimized settings of key machining factors like pulse on time, gap voltage, flushing pressure,input current and duty cycle on the material removal,surface roughness is been carried out using central composite design. The output responses measured were material removal rate (MRR) and surface roughness. Mathematical models are proposed for the above responses using response surface methodology (RSM). The results reveals that MRR is more influenced by peak current, duty factor. Finally, the parameters were optimized for maximum MRR with the desired surface roughness

KEYWORDS:

Response surface methodology; Central composite design; MRR

Copy the following to cite this article:

Vishwakarma M, Khare V. K, Parashar V. Response Surface Approach for Optimization of Sinker Electric Discharge Machine Process Parameters on AISI 4140 Alloy Steel. Mat.Sci.Res.India;9(1)

|

Copy the following to cite this URL:

Vishwakarma M, Khare V. K, Parashar V. Response Surface Approach for Optimization of Sinker Electric Discharge Machine Process Parameters on AISI 4140 Alloy Steel. Mat.Sci.Res.India;9(1). Available from: http://www.materialsciencejournal.org/?p=1192

|

Introduction

Electrical Discharge Machining (EDM) is a unconventional manufacturing process based on removal of material from a part by means of a series of repeated electrical sparks created by electric pulse generators at short intervals between a electrode tool and the part to be machined emmersed in dielectric fluid. At present, EDM is a widespread technique used in industry for high precision machining of all types of conductive materials such as metallic alloys, metals, graphite,composite materials or some ceramic materials. The selection of optimized manufacturing conditions is one of the most important aspects to consider in the die-sinking electrical discharge machining (EDM) of conductive steel, as these conditions are the ones that are to determine such important characteristics: surface roughness, electrode wear (EW) and material removal rate (MRR). In this paper, a study will be perform on the influence of the factors of peak current, pulse on time, interval time and power supply voltage. Isothermal aging of material varies the EN-19 steel, which is mainly used in various elements like gears, axels, drive shafts,induction hardening pins and high strength shafts1. Design of experiments (DOE) technique to select the optimum machining conditions for machining AISI 4140 using EDM. The objectives of this paper are stated as follows:

To evaluate the performance of EDM on AISI 4140 with respect to various responses such as surface quality,material removal rate(MRR).

To establish mathematical model for all responses involved which are surface quality, material removal rate (MRR).

Full factorial method from design of experiment (DOE) used in order to analyze and determine feasible solutions for optimal cutting parameters of EDM operation.

Process Parameters

The process parameters can be divided into two categories, i.e., electrical and non-electrical parameters.

Electrical Parameters

Main electrical parameters are peak current ,discharge voltage,pulse duration and pulse interval, polarity,electrode gap. Discharge voltage is related to spark gap and breakdown strength of the dielectric fluid.The open-gap voltage before electric discharge increases until ionization path is created between workpiece and electrode. Once the current starts flowing, the voltage drops and stabilizes at the working gap level. Thus a higher voltage setting increases the gap, which improves the flushing conditions and helps to stabilize the cut. Peak current is the amount of power used in discharge machining and is considered as most significant process parameter. The current increases until it reaches a preset level during each pulse on-time, which is known as peak current. Peak current is governed by surface area of cut.Higher peak current is applied during roughing operation and details with large surface area. This is the most important parameter because the machined cavity is a replica of tool electrode and excessive wear will hamper the accuracy of machining. New improved electrode materials like graphite, can work on high currents without much damage.1 Pulse duration is commonly referred to as pulse on-time and pulse interval is called pulse off-time. These are expressed in units of microseconds. Since all the work is done during pulse duration, hence this parameters and the number of cycles per second (frequency) are important. Material removal rate (MRR) depends upon the amount of energy applied during the pulse duration.13 Increased pulse duration also allow more heat to sink into the workpiece and spread, which means the recast layer will be larger and the heat- affected zone will be deeper. Material removal rate tends to decrease after an optimal value of pulse duration. Pulse interval mainly affects machining speed and stability of cut. Shorter interval, results in faster machining operation.

Literature Review

Electrical Discharge Machining (EDM) – Sinker EDm is one of the most widely used unconventional material removal process.Its typical feature of using thermal energy to machine electrically conductive job piece regardless of hardness has been its distinctive advantage in the manufacture of mould, die, automotive, defence, aerospace and surgical components. In addition, EDM does not make direct contact between the electrode and the workpiece eliminating mechanical stresses, chatter and vibration problems during machining.²Based on Yussni (2008), the variables parameters are have great effects to the machining performances results especially to the material removal rate (MRR), electrode wear rate and surface quality. There are two major groups of parameters that have been discovered and categorized2

Non-Electrical Parameters

Injection flushing pressure

Rotational of speed electrode

Electrical Parameters

Peak current

Polarity

Pulse duration

Power supply voltage

In the other hand, Van Tri (2002) categorized the parameters into five groups3:

Dielectric fluid; type of dielectric, temperature, pressure, flushing system .

Machine characteristics; servo system and stability stiffness, thermal stability and accuracy.

Tool; material, shape, accuracy

Workpiece

Adjustable parameters; discharge current, gap voltage,pulse duration, polarity, charge frequency, capacitance and tool materials.

Erden4 proposed that material removal mechanism relating to three phases of sparking,namely breakdown, discharge and erosion. Also, it was found that reversing the polarity of sparking alters the material removal phenomenon with an appreciable amount of electrode material depositing on the workpiece surface.5 Gadalla and Tsai6 investigated the material removal of WC–Co composite. They attributed the material removal to the melting and evaporation of disintegrated Co followed by the dislodging of WC gains, which have a lower electrical conductivity. However, thermal spalling contributes to the material removal mechanism during the sparking of composite ceramics. This is because the physical and mechanical properties promote abrupt temperature gradients from normal melting and evaporation.7 The working principle of EDM is shown in Fig.1. This technique has been developed in the late 1940s.8 The electrode moves toward the workpiece reducing the spark gap so that the applied voltage is high enough to ionize the dielectric fluid.9 Short duration discharges are generated in a liquid dielectric gap, which separates electrode and workpiece.

The material is removed from tool and workpiece with the erosive effect of the electrical discharges.10 The dielectric fluid serves the purpose to concentrate the discharge energy into a channel of very small cross sectional areas. It also cools the two electrodes, and flushes away the products of machining from the gap. The electrical resistance of the dielectric influences the discharge energy and the time of spark initiation.11 Early discharge occurs due to low resistance.If resistance is more, the capacitor will obtain higher charge value before initial discharge. A servo system is present to compares the gap voltage with a reference value and to ensure that the electrode moves at a proper rate to maintain the correct spark gap, and also to retract the electrode if short circuiting occurs. When the measured average gap voltage is higher than that of the servo reference voltage, preset by the operator, the feed speed increases.On the contrary,the feed rate decreases or the electrode is retracted when the average gap voltage is lower than the reference voltage, which is the case for smaller gap widths resulting in a smaller ignition delay. Thus, short circuits occured by eroded particles and humps of discharge a crater are avoided.

It has been observed that there is very little or no work represented on AISI 4140 & no model is available to represent MRR for AISI 4140 with combination of work piece and electrodes And hence the study is focused on AISI 4140 machining cavilty with various input parameters like current, pulse on time, gap voltage, duty cycle to obtain better MRR.These have been done using Central composite design technique of design of experiments.Central composite design technique is design of experiments (DoE) utilized because the experimental design and analyze of the results can be done with less effort and expenses. Since the method enormously reduces the number of experiments, quality loss of results must be taken into account.12

Figure 1: Working principle of EDM[10]

Experimental

Test Piece And Electrode Material

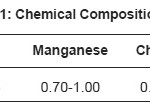

The test piece material was AISI 4140 with chemical composition given in Table 1. AISI 4140 is preferred in defence and health care due to its specific properties essential in manufacturing. Components of mediums & large cross section, requiring high tensile strength & toughness for automatic engineering and gear & engine construction such as crane shafts steering knocking connecting rods are also made from this material.

Table 1: Chemical Composition(%)

Characteristics

A 6% allowance should always be made for removal of surface defects during machining Machinability good Ideal for 60 ton tensile applications up to 100mm max. Sizes above limited ruling section will be heat treated to a hardness only, with no guarantee on mechanical properties Weldable.

Typical Applications

Axles, Connecting Rods, Drive Shafts, Crankshafts, High Tensile Bolts, Studs And propeller Shaft Joints.

Experimental

The experiments were performed on AISI 4140 test pieces (100 mm x 100 mm x 21mm) using Electronica ENC series EDM machine shown in fig below:

Figure :2

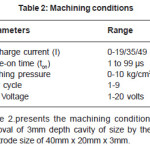

Table 2: Machining conditions

Measurement Procedure

The test piece was weighed before and after drilling operation using a digital precision scale. Material Removal Rate (MRR) for each experiment was calculated by the following formula:

MRR (mg/min) = initial weight – final weight / machining time … (1)

Mathematical Modelling

Design Of Experiments

Design of Experiments (DOE) is a method to obtain useful information about a process by conducting only minimum number of experiments.13 Each controllable variable (Ip, Ton,Vgap,, Tduty cycle,Flushing pressure) can be set on EDM machine at five consecutive levels from 1 to 5, and hence the design consisting of 30 experiments based on Central Composite Design (CCD) was generated at these levels using Minitab® statistical software.Other factors given in Table 2 were kept constant. Table 3 shows the design matrix with experimental plan. MRR predicted within error range of ± 16% (except experiment no. 29) and ± 19%, respectively.

The selected three parameters have different influences on the machining performance. The MRR is calculated 3 by dividing the volume of material removed by the actual machining time and expressed in mm3/min. The coefficients of the response surface equation were determined by using Minitab15 software.

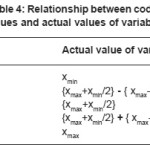

Statistical Analysis

A five factors, five evel Central Composite design was use to determine the optimal levels of machining parameters of sinker EDM machine for AISI 4140 alloy steel. The central composite design (CCD) with a quadratic model was employed.14Five independent variables namely current, voltage gap,duty cycle,flushing pressure are chosen. Each independent variable had 5 levels which were – 1, 0 and +1. A total 30 different combinations including 8 axial runs and 6 center point runs.The value of alpha here is (-2,2) as per CCD chart for five factorial experiment.The experiments were run in random order according to a CCD configuration for five factors. The coded values above in table 3 were obtained as per the following relationships in table 4 :

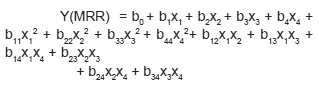

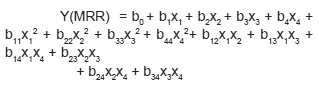

A second-order polynomial equation was proposed to express the MRR as a function of independent variables.Response surface model is hereby employed as a hybrid mathematical and statistical method in which a response(MRR) of interest is affected by several variables and the objective is to optimize this response.13 In this study, a second-order polynomial was selected to develop empirical equations to represent responses MRR in terms of controllable variables (Ip, Ton,Tduty cycle,Vgap):

Table 3: Experimental plan in accordance to CCD

Table 4: Relationship between coded values and actual values of variables

Experimental Results & Scope

Effect of Voltage on MRR

In EDM operations, the voltage is one of the important parameters. To study the effect of voltage,the spark gap and capacitance were kept constant. With analysis, it is observed that, with increase in voltage, the MRR also increases. This occurs because of the energy discharge from the electrode increases with increase in voltage. With increase in discharge energy, higher temperatures are generated between the electrodes. This results higher in MRR.

The capacitance is also an influencing parameter in EDM. To study the effect in capacitance, other two parameters such as voltage and spark gap are kept constant.This is another scope for further study and analysis in EDM research.

Conclusion

A Central composite design was used to conduct the experiments. The effect of important process parameters in EDM: voltage,current,duty cycle and flushing pressure on MRR has been studied. The following are some of the salient conclusions that could be drawn based on the studies:

Increase in voltage results in higher MRR and similarly higher capacitance results in higher MRR.

In case of spark gap, with increase in spark gap the MRR decreases.

The results obtained would be a good technical database for the defence/automotive industries.

References

- A.Gopichand,Dr.M.Muralidhara rao, Prof A.V.N.L.Sharma V.Samuel Tony. Analysis and Estimation of Attenuation Coefficient of Aging EN-19 Steel, International Journal of Engineering Research and Applications, 2(1): 590-595 (2012).

- Mr. Mohd Yussni Bin Yaakob, Electrical Discharge Machining-Die Sinking.Universiti Tun Hussein On Malaysia (UTHM) (2008).

- Van Tri, N., Electrical discharge machining of aluminum alloy using classical design of experiment approach. Universiti Teknologi Malaysia: Master Thesis (2002).

- Erden, A., “Effect of materials on the mechanism of electric discharge machining (EDM)”, J. Eng. Mater. Technol., 105: 132-138 (1983).

CrossRef

- Gangadhar, A., Sunmugam, M.S., Philip, P.K., “Pulse train studies in EDM with controlled pulse relaxation”, Int. J. Mach. Tools Manuf., 32(5): 651-657 (1992).

CrossRef

- Gadalla, A.M., Tsai, W., “Machining of WC– Co composites”, Mater. Manufacturing Processes, 4(3): 411-423 (1989).

CrossRef

- Lee, T.C., Lau, W.S., “Some characteristics of electrical discharge machining of conductive ceramics”, Material Manufacturing Processes, 6(4): 635-648 (1991).

CrossRef

- Singh, S., Maheshwari, S., Pandey, P.C.,“Some investigations into the electric discharge machining of hardened tool steel using different electrode materials”, Journal of Materials Processing Technology, 149: 272–277 (2004).

CrossRef

- Bojorquez, B., Marloth, R.T., Es-Said, O.S., “Formation of a crater in the workpiece on an electrical discharge machine”, Engineering Failure Analysis, 9: 93-97 (2002).

CrossRef

- Marafona, J.; Chousal, A.G., “A finite element model of EDM based on the Joule effect”, Int. J. Mach. Tools Manuf., 46(6):595-602 (2006).

CrossRef

- Kuneida, M., Lauwers, B., Rajurkar, K.P., Schumacher, B.M., 2005 “Advancing EDM through fundamental insight into the process”, Annals of CIRP, 54(2): 599-622.

CrossRef

- Dr. S. S. Khandare & Mitesh a. Popat, Experimental Investigations of EDM to optimize Material Removal Rate & Surface Roughness through Taguchi’s Technique of Design of Experiments. IEEE explore,ICETET-09, pg 476 – 482 (2009) .

- Montgomery, D.C., Design and analysis of experiments. Wiley (New York), ISBN: 0-471- 15746-5 (1997).

- Box, G.E.P., Hunter, W.G., Hunter, J.S., Statistics for experimenters, John Wiley, New York (1978).

This work is licensed under a Creative Commons Attribution 4.0 International License.

Material Science Research India An International Peer Reviewed Research Journal

Material Science Research India An International Peer Reviewed Research Journal